Installation of iron doors with your own hands, photo report. How to install the front door yourself: step-by-step instructions

If you are reading this article, then it’s time to install or replace your front door. A properly installed front door can not only protect you and your home from unwanted guests, but also save the precious warmth of your home. The reliability of the entire door depends not only on the manufacturer, but also directly on the quality of installation.

Often this operation is trusted only to specialists, assuming that they will do everything correctly. But when installing a metal entrance door with your own hands, you will be completely sure that everything was done conscientiously. Plus, you save a considerable amount of money (generally, the installation team takes half the cost of the door for the work). There is no point in saving on materials, because you are trying for your own good. In order to complete all the work as correctly as possible, we created this article.

Removing the old front door

Down with the old doors! Removing the front door is not a tricky task. There is no need to be very careful here (if the door is not useful in the future). You don’t have to worry about the door, but you need to take care of the integrity of the entire doorway. The less the wall is damaged during dismantling, the easier it will be to install the metal entrance door yourself. Collecting everything necessary tools and into battle!

STEP 1: remove the canvas. To simplify the process of dismantling the door, remove the door leaf from the hinges. To do this, you will need to slightly lift the canvas with a crowbar or crowbar. This operation will be successful if you take into account that you do not have a collapsible hinge mechanism. If your door has collapsible hinges, then you just need to unscrew them and remove the leaf from the opening. After removal, we set the canvas further aside, it will no longer be useful to us.

STEP 2: threshold. Installation of entrance doors is carried out in a completely cleaned doorway. Before you start removing the loot, you need to get rid of the old threshold. To make it easier to dismantle the threshold, cut it into two parts with a hacksaw and knock it out with something heavy. If you have a hammer at hand, then this can be done in 1–2 blows.

STEP 3: remove the loot. It is best to start removing the loot from the side. We make horizontal cuts on the loot with a hacksaw. Afterwards, we take our favorite crowbar and break out the loot from the opening. After side racks removed - the lintel can be removed very easily, you may not even need any additional tools.

Before installing the entrance door to the apartment with your own hands, you need to clean the doorway of old plaster and foam. If there are any fasteners of old doors left in the walls, then you need to remove them or simply cut them off with a grinder. If you still managed to dismantle the old door without destroying the wall, then all further installation work will go like clockwork.

Installation of a metal entrance door

So we cleared the doorway from the old door. Now you can start trying on the new door in the opening. For the most accurate and reliable fastening of the door in the opening, you need to disassemble the door a little. We remove the door leaf and install the door frame.

STEP 1: door frame (lutka). We place the door frame in the pre-prepared doorway. On at this stage When installing metal doors with your own hands, you should not let go of the building level. If you don’t have it, you can make it in 5 minutes. The door frame is adjusted using wooden wedge-shaped spacers.

STEP 2: Attaching the Lutka. After placing the frame in the opening, we proceed to fastening it. To securely fix the door frame, you need at least 10 fastening points. There are three types of door frame fastening.

- For the eyes

- Through the canvas of the box

- Grips

The most popular type of installation of entrance doors is the method of fastening with anchors to the eyes. Using a hammer drill or drill with an impact mechanism, a hole 15 cm deep is drilled through the eye. An anchor is inserted there and tightened with a spanner or socket wrench. Often the anchor is replaced with a metal pin. First you need to sharpen one edge of the pin, and the other, on the contrary, flatten it. It is driven into the hole until it stops and welded to the eye.

Also, the installation of the metal entrance door is carried out through the door frame itself. It has special through holes through which you need to drill the wall with a hammer drill and secure it with anchors. In this case, the anchor is tightened only with a socket wrench.

Fastening the door with metal clamps is a more complex installation option. It is used when installing entrance doors in a building with monolithic walls. The main advantage of this mount is that there is no need to drill into the wall. On the front side the door is held in place by special trims, and from the inside by metal hooks that are welded to the inside of the door frame.

STEP 3: canvas. Well, the door frame is securely in place. It's time to hang the door leaf. If your doors have non-separable hinges, then doing this will not be any problem at all. Installing a front door with your own hands is not an easy task. To simplify the whole process installation work- find someone willing to help you and just put the doors on the hinges. But if the doors are equipped with collapsible hinges, then it’s more complicated. Not only does the door need to be hung, but the hinges need to be adjusted correctly so that the closing and opening of the door is soft and clear.

Collapsible hinges

Collapsible hinges  Non-separable hinges

Non-separable hinges

After the doors are in their rightful place, they open and close without problems - we move on to the final stage - final works for upgrading the entire structure.

Installation of fittings and final finishing work

The check showed that the doors work as they should, all the gaps are even and there is no distortion. This means that the door frame is installed correctly. It's time to bring beauty around the door, and then install the necessary fittings. In order not to stain the door with foam and plaster, it is advisable to remove the door leaf and seal the door with masking tape.

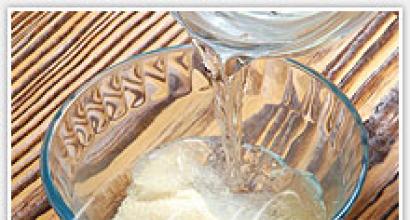

STEP 1: polyurethane foam. After installing the front door with your own hands, in any case, there will be space between the door frame and the doorway. This space needs to be filled with foam. It acts as a filler and insulation. To make the foam adhere better, we clean the opening from dust and thoroughly moisten it with water. After the polyurethane foam has completely dried, cut off the excess.

STEP 2: filling the opening. After the foam has hardened, it is necessary to level the surface of the technological gap. This can be easily done using putty.

After finishing works– we install the canvas back and continue our commissioning work.

STEP 3: platbands and slopes. After the putty has dried, we proceed to the installation of the platbands. The platbands are attached to the metal door from the outside with screws or rivets. Installing trim greatly improves the appearance of the door. From the inside of the opening, we make slopes from plaster, plastic or drywall.

STEP 4: handle and lock. The final step in the DIY door installation instructions is to install the door handle and lock. Afterwards, we check that the locks are working properly. For softer and smoother opening and closing of the lock, lubricate the mechanism with special oil. You can use a medical syringe for this. As the saying goes: “you can’t spoil porridge with butter,” and in our case, there is no such thing as too much butter.

That's all! Our step-by-step instruction I have come to the end of installing doors with my own hands. As you can see, the door installation process is simple enough to do it yourself. It is not necessary to involve specialists where you can handle it yourself.

The door is in its rightful place, fully equipped and operational. You can start daily use without fear that something will go wrong with it.

The reliability of the front door directly depends not only on its design features, but also on how correctly its installation will be done. Usually this operation is entrusted to specialists. However, sometimes the owners of an apartment or house, in order to save money, install steel entrance doors themselves. Technologically, the procedure is not particularly complicated, but some installation rules must be followed.

How to choose a door

When selecting a metal entrance door, you need to consider several factors:

What you need to know

Some manufacturers provide a warranty on front door repairs only if they were installed by licensed specialists. Others allow, among other things, do-it-yourself installation. You should find out in advance whether it will be possible to subsequently repair the door structure at the manufacturer’s expense after installation with your own hands.

Some manufacturers provide a warranty on front door repairs only if they were installed by licensed specialists. Others allow, among other things, do-it-yourself installation. You should find out in advance whether it will be possible to subsequently repair the door structure at the manufacturer’s expense after installation with your own hands.

Before buying a door in a store, you must measure the opening. The choice should be made in such a way that subsequently around the frame along the entire perimeter there remains technological gap at least 1.5 cm wide. If doors of suitable sizes cannot be found, you will, on the contrary, have to adjust the opening. They widen it with a grinder and a diamond wheel for concrete. You can already make an opening using steel channels or cement mortar on reinforcement driven into the ends of the wall.

You need to measure the opening not only in length and width. You should definitely make sure that wall thickness is more than 150 mm. According to the regulations, metal doors cannot be installed in openings of smaller depth. Reliably protect interior spaces in this case it will fail. Walls that are too thin will have to be thickened before installing the door. For this, cement mortar is usually used.

TO brick walls or lined with foam concrete blocks, it is highly not recommended to fasten the door directly. The masonry simply cannot bear the weight of the steel sheet and frame. In this case, a concrete contour is usually poured into the opening. At the same time, it is also mandatory reinforcement embedded in masonry is used. In brick and block homes, it is also recommended to measure the support beam before installing the door. Its length should be at least 4 cm greater than the width of the frame. Otherwise, the door will not hold securely in the opening.

Installation steps

Do-it-yourself installation of metal entrance doors includes the following steps:

- dismantling the old door;

- preparation of the opening;

- installation new door;

- processing of technological openings;

- installation of platbands and fittings;

- installation of slopes.

Of course, before installation you should prepare all the necessary tools and materials. A home craftsman will need a hammer drill, anchor bolts, possibly a welding machine, wooden wedges, a heavy hammer, foam, and a building level.

How to dismantle an old door with your own hands

Of course, before installing the entrance metal door structure, you should remove the old frames and leaf. This operation is not performed only if the opening needs to be greatly expanded. Wherein the walls are cut with a grinder according to the markings, and then the door is simply removed with their unnecessary parts around the perimeter.

Of course, before installing the entrance metal door structure, you should remove the old frames and leaf. This operation is not performed only if the opening needs to be greatly expanded. Wherein the walls are cut with a grinder according to the markings, and then the door is simply removed with their unnecessary parts around the perimeter.

The method for dismantling an old front door with your own hands depends on what material it is made of. Wooden structure removed like this:

- They take the canvas out of the box, prying it from below with a crowbar.

- Remove the threshold.

- Unscrew the mounting bolts around the perimeter of the box and remove it. If the frame is attached to the wall with nails, they usually act a little differently: they cut the vertical posts into two parts and remove each of them using a crowbar.

A metal door can be dismantled with your own hands as follows:

- Also remove the fabric from the hinges if they are non-separable. The collapsible ones are simply untwisted.

- Use a grinder to cut off the fastening rods.

- Remove the box from the opening.

- Seal up too large recesses at the ends of the opening with cement mortar. It is not necessary to align the ends themselves. During the door installation process, chips will still appear in them.

Preparing the opening

After the door is removed, crumbling concrete, remnants of old insulation, etc. are removed from the opening. Also check the condition of the floor where the door will subsequently be installed. Since the structure is quite heavy, if necessary, logs and beams are replaced, new boards are installed, etc.

Installation of a new door

This operation is most often performed using one of two common technologies: on the lugs or directly by attaching the frame to the ends of the opening. In the first case, the DIY installation procedure will include the following steps:

Installing a metal entrance door directly into the opening with your own hands is done in much the same way. Only the frame is attached to the wall in a slightly different way. Holes for anchors in the pillars of modern doors are usually already provided by the manufacturer. If they are not there, you will have to drill them yourself. It should be taken into account that the frame must be attached to at least three anchors on each side. It is also advisable to fix it in the opening at the top and bottom (two anchors each).

After the holes are drilled, the frame is inserted into the opening and fixed to the anchors with leveling. You can also attach it to rods. In this case, sockets are pre-drilled at the ends of the wall. Then rods are driven into them through the holes in the frame. One end of the latter should first be sharpened, and the second should be flattened. After the rods are inserted into the sockets, they are welded on the outside of the frame through the side holes. It is impossible to fasten it from the inside, since in this case, due to the swelling, the canvas will no longer close.

Processing of technological gap

After the door is installed and adjusted, we begin to process its contour. Technological gap can be sealed with foam. It is better to use the version that expands the least and is suitable for work in interior spaces.

A day after pouring, the remaining foam is cut off using a mounting knife.

In order for the door to retain heat better, the technological gap should be filled with pieces of mineral wool before using foam. You can also use cement-gypsum mortar to treat the door contour. In this case, the finish will be more durable and durable.

Installation of platbands and fittings

After sealing the technological gap with foam or mortar, you can begin installing the platbands. To wooden boxes they usually fastened using self-tapping screws with recessed heads and subsequent puttying of the nests. The platbands are fixed to metal frames with bolts with decorative caps or rivets.

At the final stage, you will need to screw the handle to the metal entrance door leaf. Next, it’s worth checking the door leaf and lock again for ease of opening/closing, after which the door can be put into operation.

Slope finishing

When dismantling the old and installing a new metal entrance door, the material of the slopes will most likely be damaged. Of course, in order for the entrance area to look aesthetically pleasing, restoration work will have to be carried out. Depending on the design of the hallway, the slopes can be finished decorative plaster, wallpaper, panels etc. They are most often first leveled using gypsum plasterboard or ordinary cement plaster.

When dismantling the old and installing a new metal entrance door, the material of the slopes will most likely be damaged. Of course, in order for the entrance area to look aesthetically pleasing, restoration work will have to be carried out. Depending on the design of the hallway, the slopes can be finished decorative plaster, wallpaper, panels etc. They are most often first leveled using gypsum plasterboard or ordinary cement plaster.

As you can see, the technology for installing a metal door into an opening with your own hands is relatively simple. The most important thing is to prevent the frame from skewing and securely fix it. In this case, it will be convenient to use the door. And, of course, when performing the installation procedure you should be as careful as possible. Repairing damage (scratches and chips) on modern doors is a complex procedure and in terms of aesthetics is ineffective.

Metal doors are rightfully considered the most reliable protection of a home from the outside world. Due to the design features, many buyers prefer them. It is also necessary to note the appearance, which can look the way the buyer himself wants, due to the huge number of design variations.

Iron doors are perfect for private buildings, apartments, offices and utility rooms. Their cost varies considerably, and installation is often equal to half the cost of the metal protector itself.

We will reveal a secret to thrifty owners: if you do the installation yourself, then with the money you save you can purchase an example of increased safety and comfort, which includes noise and heat insulation and absence of foreign odors(in the event of a fire on the site, a good door will prevent carbon monoxide from entering the apartment).

Tools and materials

For self-installation need tools for work. A rough list includes:

- Hammer or electric hammer drill;

- Building level;

- Crowbar;

- Convector with electrodes;

- Hammer;

- Grinding machine with cutting disc;

- Screwdriver (Phillips and slotted) and wrench;

- 5m tape measure;

- Simple pencil, marker.

Materials and components include:

- Anchor bolts (anchors), the size of which is not less than 100x150mm.

- Set of hexagons;

- Metal fittings, with a cross-section of 10-12 mm (if the door will be fixed by welding);

- Foam for installation - for filling the voids between the door frame and the ends of the opening;

- Spacer bars, they are a set of wooden wedges of different cross section and are needed for temporary fixation in the door frame opening, with their help they also check the correct verticality and horizontality of the structure;

- The solution will be needed if the doorway was enlarged carelessly and the gap between the opening and the frame is more than 25 mm;

- Solid oil for the closure mechanisms of the hinges and the door itself;

- Big bags for waste;

- Broom and dustpan;

- Thick cardboard to protect the floor covering from mechanical impact;

- Covering material for furniture if it is located next to the door. It will protect you from construction dust and dirt.

How to take correct measurements yourself?

For a high-quality installation, making accurate calculations of parameters is one of the most important operations. If for some reason an inaccuracy creeps into the calculations, you need to measure again and install the door again.

Exist standard sizes entrance metal doors (frames and leaves) of residential premises. Dimensions of built-in blocks:

- 860*2050 mm - it requires an opening width of 880 to 960 mm, height of 2070 to 2100 mm;

- 960*2050 mm – width should be from 980 to 1060 mm, height from 2070 to 2100 mm;

- 880*2050 mm – from 900 to 980 mm wide and from 2070 to 2100 mm high;

- 980*2050 mm – from 1000 to 1080 mm in width and from 2070 to 2100 mm in height.

For non-residential entrance groups, the parameters are non-standard and individual. The fact is that there are a huge number of GOSTs; there are no exact criteria and definitions to somehow systematize the concept of non-residential entrance openings.

Measurements are made in several stages:

- It is necessary to calculate the width of the opening from wall to wall and the height from the top edge to the bottom. If there are platbands from the old door, they must be removed and then deal with the calculations;

- If the opening differs from the standard parameters, then it needs to be narrowed or widened. The choice is made based on considerations of what is faster and more economical;

- Unforeseen circumstances, in the form of poorly reinforced or crumbling walls, must be eliminated, then measurements must be taken.

Dismantling of external iron models

The disassembly of the old door must be taken with full responsibility, since incorrect actions can lead to deformation of the opening and even injury. Dismantling metal samples, including steel, yourself is not as difficult as it might seem at first glance. However, you need to clearly follow the sequence of actions and be careful.

The action plan is:

- Preparing the necessary tools (nail puller, crowbar, hammer, stationery knife, screwdriver, pliers).

- Remove the panel (door). If the structure is secured with universal hinges, then you will need to unscrew the screws when there are card or detachable hinges - in this case, you can remove the canvas quite quickly.

- It is necessary to remove the platbands.

- We remove the door frame. You need to find a place in the wall where the box is attached (most often it is located next to the hinge or lock connection). After the fasteners are unscrewed, dismantling is completed.

Important points:

- If you can’t remove the fasteners, you can use a grinder and carefully cut them off. It is necessary to note the safety rules - use gloves and special glasses. It is also recommended to use a new circle so that it ensures correct cutting, and the device should not rest against the door frame;

- if the cutting wheel does not fit between the frame and the opening, it is necessary to increase the gap by hollowing out the plaster using a pick, which is inserted into the hammer drill chuck;

- cutting of pins is carried out strictly according to the rule (threshold of the box - sidewall - top part), if you disturb the order, the box will fall with all the ensuing consequences;

- if there is old polyurethane foam, it can be removed with a sharp utility knife, and the plaster can be removed with a hammer.

Preparing the opening

Preparing the opening is an important part of replacing a door. It does not always turn out that it fully corresponds to the parameters of the built-in input group. Let's consider several options for changing the dimensions of the doorway.

Magnification (expansion)

This can be done in two ways:

- The most common expansion method is felling, as it does not require significant cash costs. After cutting, the finished opening can already be leveled and plastered. You can cut on one side or on both sides.

- Cutting. The method is a little expensive, its advantage lies in the use load-bearing walls, any level of strength. To carry out this procedure, you need specialized equipment with a diamond disc.

Narrowing of the opening

Reducing the size must be done with the expectation of maintaining the strength of the structure, as well as its reliability. In any case, it is necessary to tie it to the main wall with steel reinforcement. There are 2 ways to reduce parameters:

- brickwork. Manufacturing is carried out both in one brick and in several, up to the right size. 3 days after working with brick, plastering is carried out. And the door leaf can be installed no earlier than after 10-14 days;

- concreting.

It is worth noting another alternative option for narrowing the doorway - this is the installation of a double door, where the small leaf does not need to be opened every time. Its advantage is that it can be opened by widening the opening when it is necessary to bring in a large item.

Mounting options

At the moment, three methods are known for fixing the entrance metal door to the frame:

- Directly in the wall, recessed method. The thickness of the walls must be at least 200 mm, otherwise any intruder will be able to break down such a door. Anchor bolts are used as fastening; holes must be made for them in advance, taking into account the technological gaps. When the work is finished, the ears of the bolts are masked with special plugs in the color of the box itself.

- On mounting plates. Installation is carried out on plates that protrude from the door block; their number is usually 3 or 4. They have special holes for mortgages. After correct placement There should be a gap of approximately 10–20 mm around the door frame around the perimeter. Then steel guides are installed in the holes, the remaining ends are welded or riveted. As a replacement for guides, you can use anchor bolts or reinforcement.

- Combined, which involves combining the first and second methods.

DIY installation rules

Inserting both metal doors into an apartment yourself is a difficult task, but doable. The whole process is divided into several stages:

- Installation of the door frame. It is fixed with wooden blocks; their thickness should slightly exceed the technological gaps. Wedges need to be driven between the box and the opening, then check with a level that the position is correct.

The upper corner of the hinge side is the beginning of the installation of the box. Next, you need to drill holes through the plates, the diameter of the holes will be 15 mm, the depth will be 100 mm. We hammer pins or bolts into them, which are welded to the plates. Then we check the level of the box.

- Test hanging of the door leaf. Once the fixation of the frame is completed, it is necessary to hang the door itself to check its movement. The door movement should not require any effort. Then we remove the canvas

- Installation of fasteners. We fix the fasteners on the false side, blow out the indentations with polyurethane foam, and remove the excess. Afterwards we install the accessories and cashing.

- Hanging the canvas. The final point is to hang the door leaf, lubricate the hinges, and install the linings.

Let's consider several technologies for installing metal doors. The first technology is installation in a wooden box. Attaching metal to wood modern conditions- a very real task. Let's note a few nuances:

- wooden buildings (a log house made of solid logs, as well as private wooden buildings, made of mini-timber or log houses) have their own shrinkage (8-12 cm). If the building is more than 5 years old, you don’t have to worry about changing the design parameters;

- for installation in wood, a semi-rigid fastening of the canvas in a box is used, while only external hinges are used.

If foam blocks, gas silicate blocks in aerated concrete block walls, or polystyrene concrete slabs are used for construction, then due to the low strength of the compositions, a feature of installing doors in such houses is additional reinforcement. This is possible in several ways:

- embedded part;

- metal structure;

- wood construction.

In frame and panel houses, for structural strength, doorways can be strengthened with additional spacers and posts; for greater reliability and rigidity, they are made of timber.

How to install a turn signal?

A turn signal or a latch handle is also called a night watchman, as this is an additional protection for the door from the entry of unwanted “guests”. This mechanism sets the latch in motion; it is installed on the inside of the door, as a result, opening it from the outside is absolutely impossible. This device is installed in several stages:

- first drill into in the right place the end of the door, the so-called “ seat» for the body of the valve itself;

- form a special pocket on the counter part of the door block;

- install the locking bolt;

- Drill a hole of suitable diameter to the rod on the inside of the door and install the turn signal.

The nuances of installing a vestibule door on the landing

The tambour door serves as additional protection against intruders entering the apartment. Installing such a door allows you to carve out space for personal belongings, for example, a baby stroller or a bicycle, without worrying about their safety and freeing up space in the apartment.

“Corridor doors” according to their design characteristics are divided into several types:

- a door with one leaf in the center and blank sides. Such blocks are installed in rooms with wide and low openings;

- a metal door with two opening doors, one of them is the main one, the other opens if necessary and is locked mainly with a latch;

- combined models. Due to the transoms, which can be movable, the passage can be expanded. In the case of blind transoms, parts of the door block will be motionless. These samples are installed in rooms with high ceilings and wide openings.

The process of installing a vestibule door is quite similar to installing an entrance door. Points characteristic of installing a common door on a landing:

- if the door already existed, then it is advisable to adjust the key holes and attachment points in the new door;

- strict adherence to the correct installation of vertical and horizontal lines;

- After completing the installation work, you must wait and do not use the door immediately. This is necessary so that the polyurethane foam that was used can dry.

How to check if the installation is correct?

In order for a metal door to serve for a long time, it must be installed correctly. There are several ways to check for deviations from the norm:

- Open and close the door. This checks the accuracy of the level and the presence of distortions. It should not open spontaneously. Only by applying external forces can you influence the canvas.

- The interval between the frame and the door. It should be kept to a minimum, as the seal will compensate for it. The seal also performs another very important function - it insulates sounds and heat.

- The presence of an interval between the doorway and the frame. It doesn't have to be big, but its presence is mandatory. It largely depends on the correct choice of the size of the door itself.

- Weight of the front door. It depends on the material and technical characteristics block (profile, corner, combined). The heaviest is the combined metal structure, due to the fact that a bent profile was used in its manufacture, which means it is the most stable and reliable. Once the installation of the door is completed, try to influence it, the force you apply should not be too great. But even if you are not entirely comfortable due to the heaviness, this issue can be resolved with the help of a suitable platband.

- Door knob and a castle. The handle should not dangle or be flimsy, nor should it be hard to press. Balance is important here. Any fittings, including those for doors, must perform well in use from the first day of installation and for a very long time. After assembly in the door, the lock should also show itself. Modern models are developed from the very beginning without any defects, so a new lock should not be given a chance to be developed. It should be easy to use without effort.

- Door hinges. For full operation they must be lubricated during installation. Otherwise, the opening mechanism will be damaged.

- Appearance doors. There should be no scratches, much less dents, on the canvas. If these appear during transportation and installation (that is, with minimal impact on the surface), then there is no need to talk about its protective anti-vandal functions; immediately discard a sample of this quality. The same can be applied to decorative elements on the door. If the door block is additional elements intact - you can be sure that you have a high-quality model.

Installing metal doors will make those who decide to do it for the first time sweat. But without this stage, repairs or completion of construction are impossible, so we decided to help and collected the experience of professionals in this article.

A little about entrance doors

Probably the most conservative interior detail of any apartment is the front door, which more and more men are trying to install with their own hands. Both metal and wooden models are equally popular. Having gone through an evolutionary path from a skin blocking the entrance to a cave to a modern armored miracle with sophisticated locks, it essentially remained what it was intended for - a kind of boundary defining the boundaries of ownership. Installing an entrance door today, in addition to creating a barrier at the entrance to the room, also serves the purpose of keeping out the cold.

As a rule, they are hinged. This type is also divided into “right” and “left”, depending on where the loops are located. The main disadvantage of installing a swing-type entrance door is the need for space to open. Because of this, it is necessary to make appropriate changes to the layout of any room where this type is provided. The point is not only in the radius of its opening (it must be indicated on the plans), it is also necessary to take into account the fact that in addition you will have to leave space for a person to pass, but he may have a rather voluminous object in his hands.

Basic materials for entrance doors

More often than others, when installing metal entrance doors, you encounter those that are made according to the standard specified by the model with the SL-2000 index. The basis for it is two sheets of alloy steel 1.5 mm thick and welded together at 200 points with horseshoe-shaped ribs. The lock must be cylindrical in shape and have up to 9 steel bolts (made of a hardened alloy), which, during locking, enter the walls and floor on all four sides of the door. If you assemble the metal door before installing it, the thickness will be at least 50 mm.

Opening and closing such a product is easy and silent. The design is simple, does not distinguish it from other doors, and does not attract attention. If you have to install the front door yourself, then it is interesting to know that its total weight (without frame) is 50 kg. A prerequisite for safety is the purchase of an additional end valve and a telescopic peephole with a large viewing angle. It is also believed that if you install a metal door according to all the rules and using special materials, then it will have impeccable sound insulation.

The dimensions of the product are not strictly established; they can be made different in accordance with the client's requirements. In external and interior decoration Both natural and artificial materials are used. The apartment looks very solid after installing metal entrance doors with wood trim. As an additional safety measure, it is possible to equip it with a special part (“insert”), which increases the height and weight of the structure.

One step below the installation of metal doors are models whose construction uses aluminum and PVC profiles. Don't be disrespectful similar designs. Yes, they are a little weaker than steel ones, but the cost for the blade itself and its installation is much lower. As a rule, Chinese enterprises supply such products. The doors are assembled industrially, and this guarantees that their quality is at the proper level. Don't forget that there are laws. This means that if an official store accepted a Chinese door for sale, the quality requirements adopted in our country are fully met.

Oddly enough, the industry does not forget about the production of wooden entrance doors. They did not become very popular, but with the development of demand for products with an increased level of safety, the requirements for them also changed. Strengthening the structure, supplying wooden door hermetic seals and gaskets, the presence of a threshold.

Removing the old box

Installing entrance doors with your own hands gives many opportunities to make a mistake, which will then cause distortion, or even breakage of the product. But you don’t always want to use the help of specialists, because more and more negative reviews are addressed to installers, even from reputable companies. If personal experience In this area there is absolutely no such thing, then it is better not to take on the installation of iron (steel) doors with your own hands for now. If you have ever worked with at least wooden model, then you can try.

First you need to dismantle the front door, this can be done with your own hands or by calling professional installers, and whether it is metal or something else almost doesn’t matter. First, separate the canvas from the box. It is better, of course, to do this together with someone, because its weight may be unbearable, and removing it from the hinges can be a very traumatic task.

Next, remove the anchors and nails from the door frame that hold it in the opening. Make cuts in the sides in several places. It will be much easier to remove these elements piece by piece. Then you can remove the upper and lower parts from the opening. Difficulties may arise if you had a metal box. You can’t do without an angle grinder here. Having freed the doorway from the old structure, it is also necessary to clean it of sound and heat insulating materials and tap the edges of the perimeter with a hammer so that the remains of the mortar and plaster do not interfere with subsequent installation. Now let's move on to installing metal entrance doors.

We master installation using the most complex example

So how to install correctly front door it’s simply necessary, otherwise you’ll have to dig it back out using the method described above, that is, by destroying the structure, we’ll look at how to do this.

How to install a metal front door with your own hands - step-by-step diagram

Step 1: Adjusting the doorway

Installation can be complicated by the fact that the perimeter does not coincide in size with the new door frame. This is not necessarily a consequence of the Chinese origin of the product; often such a problem awaits you in Stalinist houses. If the new door frame is wider or higher than the opening, you will have to cut out additional space from the walls or make a recess in the place where the threshold was located.

Do not forget about the technological gaps between the wall and the door frame in order to be able to make adjustments during installation.

It happens that the door structure is smaller in width or height than the opening. This can happen when purchasing an imported product for those already mentioned with an unkind word standard buildings. Depending on the size difference (gap), adjustment work must be carried out. If it is small, literally a few millimeters, it is enough to just use door extensions. In case of a significant distance, it will be necessary to make masonry from sand-lime brick or wall stone. Don’t be lazy to make a connection with the main wall so as not to lose strength.

Step 2: Unboxing

Now let's move on to how to install an iron model of a door with your own hands. We remove the outer packaging and stop. If the door is covered with plastic film, do not rush to tear it off, because during installation there may be some sloppiness, so the protection will not be superfluous. The mounting kit for any door frame must include anchor bolts. If suddenly there are none, then you can buy them. They should be from 10 to 15 cm in length and 12–15 mm in diameter.

Step 3: Installation of the box

Together with an assistant, install the box, check it for verticality and horizontality using levels or plumb lines. Place wooden wedges and start drilling holes in the wall for anchor bolts. While working, try not to move the door frame. It is recommended to start drilling from the side where the hinges will be. After this, insert the bolts and secure the frame, periodically checking vertically and horizontally.

insulation works. Upon completion of installation, remove the polyethylene, if any, covered the door leaf, and begin installing decorative parts. It is advisable not to use the door for two days or to do so gently and as little as possible.

The threshold of a private house regularly comes into contact with moisture from shoes that have just been walked in puddles or snow. Doors at the entrance are exposed to sun rays, temperature changes and strong winds. To prevent these negative factors from spoiling the product and reducing the temperature inside the living space, it is important to correctly install entrance doors in a private home, which is carried out taking into account the negative effects and using the right materials.

Preparing the opening for installing doors to the house

It is better to replace a street door in a private house in dry, warm weather, because unforeseen difficulties and lack of experience can extend the process for half a day or more, as a result of which the living rooms will cool down if it is cold outside. It all starts with dismantling the old structure, during which the canvas is removed from the hinges, and the fastening of the door frame is cut with a grinder and a thin abrasive disc. Having plucked the frame from the wall with a pry bar, the structure is removed.

It often remains on the threshold wooden beam, on which the box was installed. It must be checked for integrity by trying to pierce it in several places with an awl. If a thick needle enters with difficulty, then the wood can be coated with paint and left. This will protect the material from moisture penetrating under the transition. When rotten, the block is removed and a similar one is placed in its place. If the threshold is made of brick, then you need to remove traces of mortar from the surface and the outside so that nothing interferes with the leveling of the door frame. To protect from the sun, it is better to equip the porch with a canopy, which will also protect from precipitation.

Install the front door in a private house it will work out easily if the dimensions of the box are 20-50 mm smaller in width and height than the dimensions of the opening. This must be taken into account at the stage of taking measurements and selecting a product. If the box fits tightly into the opening, then with uneven floors or walls, adjusting the position will become impossible, so part of the wall will have to be cut off. In a private house, it is necessary to connect lighting or an outlet to the street to connect a watering pump and other needs. One of the ways is under the door frame, so when preparing the opening for these purposes, mortgages in the form of a plastic pipe are placed.

Install the front door in a private house it will work out easily if the dimensions of the box are 20-50 mm smaller in width and height than the dimensions of the opening. This must be taken into account at the stage of taking measurements and selecting a product. If the box fits tightly into the opening, then with uneven floors or walls, adjusting the position will become impossible, so part of the wall will have to be cut off. In a private house, it is necessary to connect lighting or an outlet to the street to connect a watering pump and other needs. One of the ways is under the door frame, so when preparing the opening for these purposes, mortgages in the form of a plastic pipe are placed.

Correct installation of a street door in a private house

In order for the entrance to be well insulated from freezing, it is necessary to correctly design the junction of the frame and the wall. The installation of a street door in a private house is carried out with the door leaf initially removed so that it does not distort the structure and does not create unnecessary stress on the hands. The box is filled from the inside with foam plastic, glued to liquid nails, or mineral wool, held in place by expansion. This will protect against the formation of condensation and drips in the hallway.

In order for the entrance to be well insulated from freezing, it is necessary to correctly design the junction of the frame and the wall. The installation of a street door in a private house is carried out with the door leaf initially removed so that it does not distort the structure and does not create unnecessary stress on the hands. The box is filled from the inside with foam plastic, glued to liquid nails, or mineral wool, held in place by expansion. This will protect against the formation of condensation and drips in the hallway.

The box must be covered with masking tape so that when working with a tool or foaming the installation gap at the end, you do not spoil the powder coating. Next, installing a metal door in a private house with your own hands is possible with an assistant, due to the weight of the product 60-100 kg, and is carried out in the following sequence:

- The door frame is inserted into the opening until the platband fits completely.

- Plastic wedges are installed under it, sold in hardware stores for these purposes. In the absence of plastic devices, homemade wooden ones are used. The goal is to spread the structure to the sides.

- A bubble level is used to check the threshold relative to the horizontal and the rack to align the vertical. To raise the angle of the box or change the slope inside the opening, adjust the thickness of the wedge insertion.

- Once a level position is achieved, the drill is marked, which can be done by attaching an anchor to it and marking the end with masking tape. You need to start drilling from the top on the hinge side.

- The anchor is inserted into the hole and driven through a screwdriver. It needs to be tightened so that the fixation becomes rigid. After which a second similar fastening unit is mounted.

- Now you can hang the canvas on the hinges and make sure there are no distortions under load. When everything is in order, the remaining anchors are placed.

- When sealing an installation gap, it is better to use foam with a low coefficient of expansion, which will not create excessive pressure on the metal, but will insulate the gaps well.

The Reliable Doors company offers to install an iron door in a private house in compliance with all current building codes, which will ensure high insulation of the entrance from freezing and noise. We have extensive experience in installing doors in openings of various thicknesses and will provide correct location, promoting long-term operation.