Diagram and equipment of the thermal power plant heat supply system. Types and types of power plants

Class: 9

Goals: to form in students an idea of the Russian electric power industry as a vanguard industry National economy countries.

Tasks:

- Educational: deepen students’ knowledge of the fuel and energy complex of Russia; explain the concepts of “electric power industry” and “energy system”; give an idea of the role and importance of the electric power industry for industry and the population of the country;

- Developmental: develop students’ skills in working with maps and text; promote the development of analytical and logical thinking;

- Educational: to cultivate interest in the geography of the native country, its economy and ecology.

Lesson type: combined.

Technical training aids and material support: Computer included – 1 set, Video projector – 1 pc., Interactive whiteboard – 1 pc., Computer programs and media – 1 set, map “Electric power industry of Russia”, student atlases, presentation ( Annex 1) photographs of various power plants, diagrams, video clips.

Terminological apparatus: power plant, thermal power plant, hydroelectric power station, nuclear power plant, alternative energy sources, energy system.

Time: 45 minutes.

During the classes

I. Organizational moment (1 min.)

II. Homework survey (8 min.)

Test. Working with presentation text.

The largest coal reserves (general geological) are concentrated in: (slide 3)

A) Kuznetsk basin

B) Pechora basin

B) Tunguska basin

D) Donetsk basin

The basin ranks first in Russia in terms of coal reserves (slide 4)

A) Kuznetsky

B) Pechorsky

B) South Yakut

The cheapest coal (2-3 times cheaper than Kuznetsk) in the basin (slide 5)

A) Pechora

B) Donetsk

B) Kansk-Achinsk

The largest oil and gas base in Russia is (slide 6)

A) Western Siberia

B) Volga region

B) Barents Sea

On the territory of Russia there are (slide 7)

A) 26 refineries

B) 22 refineries

B) 30 refineries

D) 40 refineries

The total length of gas pipelines in Russia is (slide 8)

A) 140 thousand km

B) 150 thousand km

B) 170 thousand km

D) 120 thousand km

Russia ranks in the world in terms of gas reserves (slide 9)

A) 1st place

B) 2nd place

B) 3rd place

Draw a diagram “Composition of the fuel and energy complex”

Working with the text (students receive cards with the text, identify errors in it and correct them). Answers: 1) B; 2) A; 3) B; 4) A; 5) A; 6) B; 7) A. (slide 10). Peer review of work in pairs. Appendix 2

III. Studying a new topic (slide 12) (30 min.)

Plan.

- The importance of the electric power industry for the country.

- Alternative sources energy.

1. The importance of the electric power industry for the country.

Write the definition in your notebook (slide 13)

Electric power industry is an industry that produces electricity at power plants and transmits it over a distance via power lines.

Working with statistical material from the textbook table (p. 125) “Dynamics of electricity production in Russia over the past 20 years.” There was a decline in production in the late 1990s, but an increase in production at present.

Energy consumers (slide 14)

The main requirement is reliability of power supply. To do this, they try to connect all power plants with power transmission lines (PTLs), so that a sudden failure of one of them can be compensated by others. This is how the Unified Energy System (UES) of the country is formed (slide 15).

The country's UES in the electric power industry combines the production, transmission and distribution of electricity between consumers. In the power system, each power plant has the opportunity to choose the most economical operating mode. The UES of Russia unites more than 700 large power plants, which contain more than 84% of the capacity of all power plants in the country (slide 16). Map slide (slide 17).

Electricity production at different types of stations is shown in the diagram (slide 18).

Power plant location factors different types: (slide 19).

Each power plant has its own characteristics. Let's look at them.

Types of power plants:

2. TPP– thermal. They operate on traditional fuels: coal, fuel oil, gas, peat, oil shale.

Efficiency -30-70% (slide 20, 21).

Factors for placing thermal power plants (slide 22).

CHP is a type of thermal power plant (slide 23).

Advantages and disadvantages of thermal power plants (slide 24).

The largest thermal power plant in our country is the Surgut thermal power plant (a short message from a student - an advanced task) (slide 25).

The next type is

Hydroelectric power stations

3. Hydroelectric power station– hydraulic. They use the energy of falling or moving water; efficiency is 80% (slide 26).

The location of hydroelectric power stations is determined using the map “Hydropower Resources of Russia” (slide 27).

On largest rivers cascades of hydroelectric power stations were built (slide 28).

Advantages and disadvantages of hydroelectric power stations (slide 29).

The largest hydroelectric power station in Russia is Sayano-Shushenskaya (6.4 MW), where a man-made disaster occurred in 2009 (slide 30).

The Cheboksary hydroelectric power station is the closest to the Republic of Mari El (slide 31).

Nuclear power plants.

4. Nuclear power plant- nuclear power plants. They use the energy of nuclear decay.

- Efficiency -30-35% (slide 32).

The operating principle of a nuclear power plant can be seen in the video clip (slide 33) ( Appendix 3 , Appendix 4). We see the location of the nuclear power plant on the map (slide 34).

Advantages and disadvantages of nuclear power plants (slide 35).

The types of power plants considered operate on the combustion of mineral fuel, which will inevitably run out after a certain period of time. Alternative energy sources will be required to meet future electricity needs.

5. Alternative energy sources

Alternative power plants (slide 36). Let's look at the types of alternative energies.

- Solar energy. Factory under construction solar panels in Chuvashia (slide 37). (38) Solar panels are already finding practical application in the capital of the republic. In the Botanical Garden of Yoshkar-Ola, the greenhouse is illuminated and heated using solar energy (slide 39).

- Wind energy. Slide (40) shows wind engines and a windmill in the open-air museum of Kozmodemyansk, Republic of Mari El. Such mills were used in many settlements of the country.

- Internal energy of the Earth. (slide 41). In which region of the country are gas turbine power plants located? (slide 42).

- Tidal energy is used at the Kislogubskaya TPP (slide 43)

IV. Reflection (4 min.)

What new things have you learned about yourself?

- What type of power plants predominates in Russia?

- What is the difference between power plants and stations?

- Where is the best place to build a hydroelectric power station?

- Where are their nuclear power plants built?

- What is a power grid?

V. Homework (2 min).

(slide 44, 45) Read the textbook, paragraph 23. Put on the contour map: Balakovskaya, Beloyarskaya, Bilibinskaya, Bratkaya, Volzhskaya, Zeyskaya, Kola, Konakovskaya, Kursk, Leningradskaya, Obninskaya, Reftinskaya, Smolenskaya, Surgutskaya, Cheboksaryskaya. Write down the problems of the electrical power industry and try to find a solution to the problem.

For those interested:

- watch the series of programs “Energy: how it works”

- myenergy.ru

Student grades.

Thank you for the lesson!

Literature.

- Geography of Russia. Population and economy 9th grade. Textbook V.P. Dronov, V.Ya. Rum.

- Lesson developments in geography “Population and economy of Russia” 9th grade. E.A. Zhizhina.

- Atlas and contour maps in geography for grade 9.

- Virtual school of Cyril and Methodius. Geography lessons 9th grade.

- Map of Electric Power Industry of Russia Multimedia disk.

- Presentation for the lesson “Electric power engineering. Types of power plants.”

A thermal power plant is an enterprise for generating electricity and heat. When building a power plant, they are guided by the following, which is more important: the location of a fuel source nearby or the location of a nearby source of energy consumption.

Placement of thermal power plants depending on the fuel source.

Let's imagine that, let's say, we have a large coal deposit. If we build a thermal power plant here, we will reduce the costs of fuel transportation. If we take into account that the transport component in the cost of fuel is quite large, then it makes sense to build thermal power plants near mining sites. But what will we do with the resulting electricity? It’s good if there is somewhere nearby to sell it, there is a shortage of electricity in the area.

What to do if there is no need for new electrical power? Then we will be forced to transmit the resulting electricity via wires over long distances. And in order to transmit electricity over long distances without large losses, it is necessary to transmit it through high-voltage wires. If they are not there, then they will need to be pulled. In the future, power lines will require maintenance. All this will also require money.

Placement of thermal power plants depending on the consumer.

Most new thermal power plants in our country are located in close proximity to the consumer.

This is due to the fact that the benefit of placing thermal power plants in close proximity to the fuel source is eaten up by the cost of transportation over long distances via power lines. Moreover, in this case, there are large losses.

When placing a power plant directly next to the consumer, you can also win if you build a thermal power plant. You can read in more detail. In this case, the cost of supplied heat is significantly reduced.

If placed directly next to the consumer, there is no need to build high-voltage power lines; a voltage of 110 kV will be sufficient.

From everything written above we can draw a conclusion. If the fuel source is far away, then in the current situation it is better to build thermal power plants, however, close to the consumer. Greater benefits are obtained if the source of fuel and the source of electricity consumption are nearby.

Dear visitors! Now you have the opportunity to see Russia.

YOUTH AND SPORTS OF UKRAINE

YU.A. GICHEV

THERMAL POWER PLANTS

Frequentlyb I

Dnepropetrovsk NMetAU 2011

MINISTRY OF EDUCATION AND SCIENCE,

YOUTH AND SPORTS OF UKRAINE

NATIONAL METALLURGICAL ACADEMY OF UKRAINE

YU.A. GICHEV

THERMAL POWER PLANTS

Frequentlyb I

Ill. 23. Bibliography: 4 names.

Responsible for the issue, Dr. Tech. sciences, prof.

Reviewer: , Dr. Tech. sciences, prof. (DNUZHT)

Cand. tech. Sciences, Associate Professor (NMetAU)

© National Metallurgical

Academy of Ukraine, 2011

INTRODUCTION…………………………………………………………………………………..4

1 GENERAL INFORMATION ABOUT THERMAL POWER PLANTS………………...5

1.1 Definition and classification of power plants………………………….5

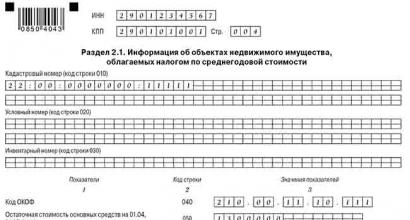

1.2 Technological diagram of a thermal power plant………………………8

1.3 Technical and economic indicators of thermal power plants……………………………….11

1.3.1 Energy indicators…………………………………….11

1.3.2 Economic indicators…………………………………….13

1.3.3 Performance indicators……………………………...15

1.4 Requirements for thermal power plants………………………………………………………16

1.5 Features of industrial thermal power plants………………16

2 CONSTRUCTION OF THERMAL DIAGRAMS OF TPP………………………………………………………...17

2.1 General concepts about thermal circuits………………………………………………………17

2.2 Initial steam parameters…………………………………………….18

2.2.1 Initial steam pressure…………………………………….18

2.2.2 Initial steam temperature…………………………………...20

2.3 Intermediate superheating of steam…………………………………………..22

2.3.1 Energy efficiency of intermediate superheating...24

2.3.2 Intermediate superheat pressure…………………………26

2.3.3 Technical implementation of intermediate superheating……27

2.4 Final steam parameters………………………….……………………….29

2.5 Regenerative heating of feedwater……………………………...30

2.5.1 Energy efficiency of regenerative heating..30

2.5.2 Technical implementation of regenerative heating.......34

2.5.3 Temperature of regenerative heating of feedwater..37

2.6 Construction of thermal diagrams of thermal power plants based on the main types of turbines……..39

2.6.1 Construction of a thermal circuit based on turbine “K”…………...39

2.6.2 Construction of a thermal circuit based on turbine “T”….………..41

LITERATURE………………………………………………………………………………...44

INTRODUCTION

The discipline “Thermal Power Plants” for a number of reasons is of particular importance among the disciplines taught for specialty 8(7). - thermal power engineering.

Firstly, from a theoretical point of view, the discipline accumulates the knowledge acquired by students in almost all the main previous disciplines: “Fuel and its combustion”, “Boiler installations”, “Superchargers and heat engines", "Heat supply sources for industrial enterprises", "Gas purification" and others.

Secondly, from a practical point of view, thermal power plants (TPPs) are a complex energy enterprise that includes all the main elements of the energy economy: a fuel preparation system, a boiler shop, a turbine shop, a system for converting and supplying thermal energy to external consumers, recycling and neutralization systems harmful emissions.

Thirdly, from an industrial point of view, thermal power plants are the dominant power generating enterprises in the domestic and foreign energy sector. Thermal power plants account for about 70% of the installed electricity generating capacity in Ukraine, and taking into account nuclear power plants, where steam turbine technologies are also implemented, the installed capacity is about 90%.

This lecture notes have been developed in accordance with the work program and curriculum for specialty 8(7). - thermal power engineering and includes as main topics: general information about thermal power plants, principles of constructing thermal circuits of power plants, selection of equipment and calculations of thermal circuits, layout of equipment and operation of thermal power plants.

The discipline “Thermal Power Plants” helps to systematize the knowledge acquired by students, expand their professional horizons and can be used in coursework in a number of other disciplines, as well as in the preparation of theses for specialists and graduate theses for masters.

1 GENERAL INFORMATION ABOUT THERMAL POWER PLANTS

1.1 Definition and classification of power plants

Power station– an energy enterprise designed to convert various types of fuel and energy resources into electricity.

Main options for classifying power plants:

I. Depending on the type of converted fuel and energy resources:

1) thermal power plants (TPPs), in which electricity is produced by converting hydrocarbon fuels (coal, natural gas, fuel oil, combustible RES and others);

2) nuclear power plants (NPP), in which electricity is produced by converting atomic energy from nuclear fuel;

3) hydroelectric power plants (HPP), in which electricity is obtained by converting the mechanical energy of the flow natural source water, primarily rivers.

This classification option can also include power plants using non-traditional and renewable energy sources:

· geothermal power plants;

· wind power stations;

· tidal power stations and others.

II. For this discipline, a more in-depth classification of thermal power plants is of interest, which, depending on the type of heat engines, are divided into:

1) steam turbine power plants (STP);

2) gas turbine power plants (GTU);

3) combined cycle power plants (CGE);

4) power plants using internal combustion engines (ICE).

Among these power plants, steam turbine power plants are dominant, accounting for over 95% of the total installed capacity of thermal power plants.

III. Depending on the type of energy supplied to external consumers, steam turbine power plants are divided into:

1) condensing power plants (CPS), which supply exclusively electricity to external consumers;

2) combined heat and power plants (CHPs), which supply both thermal and electrical energy to external consumers.

IV. Depending on their purpose and departmental subordination, power plants are divided into:

1) district power plants, which are designed to provide electricity to all consumers in the region;

2) industrial power plants, which are part of industrial enterprises and are intended to provide electricity primarily to consumers of enterprises.

V. Depending on the duration of use of the installed capacity during the year, power plants are divided into:

1) basic (B): 6000÷7500 hours/year, i.e. over 70% of the duration of the year;

2) semi-basic (P/B): 4000÷6000 h/year, 50÷70%;

3) half-peak (P/P): 2000÷4000 h/year, 20÷50%;

4) peak (P): up to 2000 hours/year, up to 20% of the year.

This classification option can be illustrated using the example of a graph of the duration of electrical loads:

Figure 1.1 – Graph of duration of electrical loads

VI. Depending on the steam pressure entering the turbines, steam turbine thermal power plants are divided into:

1) low pressure: up to 4 MPa;

2) medium pressure: up to 9 – 13 MPa;

3) high pressure: up to 25 – 30 MPa, including:

● subcritical pressure: up to 18 – 20 MPa

● critical and supercritical pressure: over 22 MPa

VII. Depending on the power, steam turbine power plants are divided into:

1) low-power power plants: total installed capacity up to 100 MW with a unit power of installed turbogenerators up to 25 MW;

2) medium power: total installed capacity up to 1000 MW with a unit power of installed turbogenerators up to 200 MW;

3) high power: total installed capacity over 1000 MW with a unit power of installed turbo generators over 200 MW.

VIII. Depending on the method of connecting steam generators to turbogenerators, thermal power plants are divided into:

1) centralized (non-unit) thermal power plants, in which steam from all boilers enters one central steam pipeline and is then distributed among turbine generators (see Fig. 1.2);

1 – steam generator; 2 – steam turbine; 3 - central (main) steam line; 4 – steam turbine condenser; 5 – electric generator; 6 – transformer.

Figure 1.2 - Schematic diagram centralized (non-block) thermal power plant

2) block thermal power plants, in which each of the installed steam generators is connected to a very specific turbogenerator (see Fig. 1.3).

1 – steam generator; 2 – steam turbine; 3 – intermediate superheater; 4 – steam turbine condenser; 5 – electric generator; 6 – transformer.

Figure 1.3 - Schematic diagram of a block thermal power plant

In contrast to the non-block design, the block design of thermal power plants requires less capital costs, is easier to operate and creates conditions for full automation of the steam turbine installation of the power plant. In the block diagram, the number of pipelines and production volumes of the station for the placement of equipment are reduced. When using intermediate superheating of steam, the use of block diagrams is mandatory, since otherwise it is not possible to control the flow of steam released from the turbine for superheating.

1.2 Technological diagram of the thermal power plant

The technological diagram depicts the main parts of the power plant, their interconnection and, accordingly, shows the sequence of technological operations from the moment of delivery of fuel to the station to the supply of electricity to the consumer.

As an example, Figure 1.4 shows a technological diagram of a pulverized-coal steam turbine power plant. This type of thermal power plant predominates among the existing basic thermal power plants in Ukraine and abroad.

Sun – fuel consumption at the station; Dp. g. – steam generator productivity; Ds. n. – conditional flow a couple for the station’s own needs; Dt – steam consumption per turbine; Evir – amount of generated electricity; Esn - electricity consumption for the station’s own needs; Eotp is the amount of electricity supplied to external consumers.

Figure 1.4 – Example of a technological diagram of a steam turbine pulverized coal power plant

The technological diagram of a thermal power plant is usually divided into three parts, which are marked with dotted lines in Figure 1.4:

I … Fuel-gas-air path, which includes:

1 – fuel facilities (unloading device, raw coal warehouse, crushing plants, crushed coal bunkers, cranes, conveyors);

2 – dust preparation system (coal mills, fine fans, coal dust bins, feeders);

3 – blower fan for supplying air for fuel combustion;

4 – steam generator;

5 – gas cleaning;

6 – smoke exhauster;

7 – chimney;

8 – slag pump for transporting hydroash and slag mixture;

9 – supply of hydroash and slag mixture for disposal.

In general, the fuel-gas-air path includes : fuel facilities, dust preparation system, draft means, boiler flues and ash and slag removal system.

II … Steam-water path, which includes:

10 – steam turbine;

11 – steam turbine condenser;

12 – circulation pump of the circulating water supply system for cooling the condenser;

13 – cooling device of the circulating system;

14 – supply of additional water to compensate for water losses in the circulating system;

15 – supply of raw water for the preparation of chemically purified water, compensating for the loss of condensate at the station;

16 – chemical water treatment;

17 – chemical water treatment pump supplying additional chemically treated water to the exhaust steam condensate stream;

18 – condensate pump;

19 – regenerative low-pressure feedwater heater;

20 – deaerator;

21 – feed pump;

22 – regenerative high-pressure feedwater heater;

23 – drainage pumps to remove heating steam condensate from the heat exchanger;

24 – regenerative steam extraction;

25 – intermediate superheater.

In general, the steam-water path includes: steam-water part of the boiler, turbine, condensate unit, systems for preparing cooling circulating water and additional chemically purified water, a system for regenerative heating of feed water and deaeration of feed water.

III … Electrical part which includes:

26 – electric generator;

27 – step-up transformer for electricity supplied to external consumers;

28 – buses of the open switchgear of the power plant;

29 – transformer for electricity for the power plant’s own needs;

30 – busbars of the distribution device for auxiliary electricity.

Thus, the electrical part includes: electric generator, transformers and switchgear buses.

1.3 Technical and economic indicators of thermal power plants

Technical and economic indicators of thermal power plants are divided into 3 groups: energy, economic and operational, which, respectively, are intended to assess the technical level, efficiency and quality of operation of the station.

1.3.1 Energy performance

The main energy indicators of thermal power plants include: efficiency power plants (), specific heat consumption (), specific fuel consumption for electricity generation ().

These indicators are called the thermal efficiency indicators of the plant.

Based on the results of the actual operation of the power plant, efficiency is determined by the relations:

![]() ; (1.1)

; (1.1)

![]() ; (1.2)

; (1.2)

When designing a power plant and analyzing its operation, efficiency. determined by products taking into account efficiency. individual elements of the station:

where ηcat, ηturb – efficiency. boiler and turbine shops;

ηt. p. – k.p.d. heat flow, which takes into account heat loss by coolants inside the station due to heat transfer to environment through the walls of the pipeline and coolant leaks, ηt. n. = 0.98...0.99 (average 0.985);

esn is the share of electricity spent on the power plant’s own needs (electric drive in the fuel preparation system, drive of the boiler shop draft equipment, pump drive, etc.), esn = Esn/Evir = 0.05...0.10 (cf. 0.075);

qсн – share of heat consumption for own needs (chemical water treatment, deaeration of feed water, operation of steam ejectors providing vacuum in the condenser, etc.), qсн = 0.01...0.02 (cf. 0.015).

K.p.d. boiler shop can be represented as efficiency steam generator: ηcat = ηp. g = 0.88…0.96 (average 0.92)

K.p.d. turbine shop can be represented as absolute electrical efficiency. turbogenerator:

ηturb = ηt. g. = ηt · ηoi · ηм, (1.5)

where ηt is thermal efficiency. cycle of a steam turbine plant (ratio of heat used to heat supplied), ηt = 0.42...0.46 (cf. 0.44);

ηoi – internal relative efficiency. turbines (takes into account losses inside the turbine due to steam friction, cross-flows, ventilation), ηoi = 0.76...0.92 (cf. 0.84);

ηm – electromechanical efficiency, which takes into account losses during the transfer of mechanical energy from the turbine to the generator and losses in the electric generator itself, ηen = 0.98...0.99 (cf. 0.985).

Taking into account the product (1.5), expression (1.4) for the efficiency net power plant takes the form:

ηsnetto = ηпг·ηt· ηoi· ηм· ηтп·(1 – есн)·(1 – qсн); (1.6)

and after substituting the average values it will be:

ηsnetto = 0.92·0.44·0.84·0.985·0.985·(1 – 0.075)·(1 – 0.015) = 0.3;

In general, for a power plant the efficiency is net varies within the range: ηsnet = 0.28…0.38.

The specific heat consumption for electricity generation is determined by the ratio:

![]() , (1.7)

, (1.7)

where Qfuel is the heat obtained from fuel combustion ![]() .

.

![]() ; (1.8)

; (1.8)

where pH is the standard investment efficiency ratio, year-1.

The inverse value pH gives the payback period for capital investments, for example, with pH = 0.12 year-1, the payback period will be:

The given costs are used to select the most economical option for constructing a new or reconstructing an existing power plant.

1.3.3 Performance

Operational indicators assess the quality of operation of the power plant and specifically include:

1) staffing coefficient (number of service personnel per 1 MW of installed power of the station), W (persons/MW);

2) utilization factor of the installed capacity of the power plant (the ratio of actual electricity production to the maximum possible generation)

; (1.16)

; (1.16)

3) number of hours of use of installed capacity

4) equipment availability factor and coefficient technical use equipment

![]() ; (1.18)

; (1.18)

Equipment availability factors for boiler and turbine shops are: Kgotkot = 0.96...0.97, Kgotturb = 0.97...0.98.

The utilization rate of equipment for thermal power plants is: KispTPP = 0.85…0.90.

1.4 Requirements for thermal power plants

The requirements for thermal power plants are divided into 2 groups: technical and economic.

TO technical requirements relate:

· reliability (uninterrupted power supply in accordance with consumer requirements and dispatch schedule of electrical loads);

· maneuverability (the ability to quickly increase or remove the load, as well as start or stop units);

· thermal efficiency (maximum efficiency and minimum specific fuel consumption under various operating modes of the plant);

· environmental friendliness (minimal harmful emissions into the environment and not exceeding permissible emissions under various operating modes of the plant).

Economic requirements are reduced to the minimum cost of electricity, subject to compliance with all technical requirements.

1.5 Features of industrial thermal power plants

Among the main features of industrial thermal power plants are:

1) two-way communication of the power plant with the main technological workshops (the power plant provides the electrical load of the technological workshops and, in accordance with the need, changes the supply of electricity, and the workshops in some cases are sources of thermal and combustible renewable energy resources that are used at power plants);

2) the commonality of a number of systems of power plants and technological workshops of the enterprise (fuel supply, water supply, transport facilities, repair base, which reduces the costs of plant construction);

3) the presence at industrial power plants, in addition to turbogenerators, of turbocompressors and turboblowers for supplying process gases to the workshops of the enterprise;

4) the predominance of combined heat and power plants (CHP) among industrial power plants;

5) relatively small capacity of industrial thermal power plants:

70…80%, ≤ 100 MW.

Industrial thermal power plants provide 15...20% of the total electricity generation.

2 CONSTRUCTION OF THERMAL DIAGRAMS OF TPP

2.1 General concepts about thermal circuits

Thermal diagrams relate to steam-water paths of power plants and show :

1) relative position of the main and auxiliary equipment of the station;

2) technological connection of equipment through coolant pipeline lines.

Thermal circuits can be divided into 2 types:

1) fundamental;

2) expanded.

The schematic diagrams show the equipment to the extent necessary for calculating the thermal circuit and analyzing the calculation results.

Based on the circuit diagram, the following tasks are solved:

1) determine the costs and parameters of coolants in various elements of the circuit;

2) choose equipment;

3) develop detailed thermal circuits.

Expanded Thermal Circuits include all station equipment, including backup equipment, all station pipelines with shut-off and control valves.

Based on the developed schemes, the following tasks are solved:

1) mutual placement of equipment when designing power plants;

2) execution of working drawings during design;

3) operation of stations.

The construction of thermal diagrams is preceded by solving the following issues:

1) selection of the type of station, which is carried out based on the type and quantity of expected energy loads, i.e. CPP or CHP;

2) determine electrical and thermal power the station as a whole and the capacity of its individual blocks (units);

3) select the initial and final steam parameters;

4) determine the need for intermediate superheating of steam;

5) choose the types of steam generators and turbines;

6) develop a scheme for regenerative heating of feedwater;

7) arrange the main technical solutions according to the thermal scheme (unit power, steam parameters, type of turbines) with a number of auxiliary issues: preparation of additional chemically purified water, water deaeration, utilization of steam generator blow-off water, drive of feed pumps and others.

The development of thermal circuits is mainly influenced by 3 factors:

1) the value of the initial and final parameters of steam in a steam turbine installation;

2) intermediate superheating of steam;

3) regenerative heating of feedwater.

2.2 Initial steam parameters

The initial steam parameters are the pressure (P1) and temperature (t1) of the steam before the turbine stop valve.

2.2.1 Initial steam pressure

The initial steam pressure affects the efficiency. power plants and, first of all, through thermal efficiency. cycle of a steam turbine plant, which, when determining the efficiency power plant has a minimum value (ηt = 0.42...0.46):

To determine thermal efficiency can be used iS– water vapor diagram (see Fig. 2.1):

![]() (2.2)

(2.2)

where Above is the adiabatic heat loss of steam (for an ideal cycle);

qsupply is the amount of heat supplied to the cycle;

i1, i2 – enthalpy of steam before and after the turbine;

i2" – enthalpy of condensate of steam exhausted in the turbine (i2" = cpt2).

Figure 2.1 – Towards the determination of thermal efficiency.

The results of the calculation using formula (2.2) give the following efficiency values:

ηt, fractions of units

Here 3.4...23.5 MPa are the standard steam pressures adopted for steam turbine power plants in the energy sector of Ukraine.

From the calculation results it follows that with an increase in the initial steam pressure, the value of efficiency. increases. Together with that, An increase in pressure has a number of negative consequences:

1) with increasing pressure, the volume of steam decreases, the flow area of the turbine flow part and the length of the blades decrease, and, consequently, steam flows increase, which leads to a decrease in the internal relative efficiency. turbines (ηоі);

2) an increase in pressure leads to an increase in steam losses through the turbine end seals;

3) metal consumption for equipment and the cost of a steam turbine plant increases.

To eliminate the negative impact Along with an increase in pressure, the turbine power should be increased, which ensures :

1) increase in steam flow (excludes a decrease in the flow area in the turbine and the length of the blades);

2) reduces the relative escape of steam through the mechanical seals;

3) an increase in pressure together with an increase in power makes it possible to make pipelines more compact and reduce metal consumption.

The optimal ratio between the initial steam pressure and turbine power, obtained based on an analysis of the operation of existing power plants abroad, is presented in Figure 2.2 (the optimal ratio is marked by shading).

Figure 2.2 – Relationship between turbogenerator power (N) and initial steam pressure (P1).

2.2.2 Initial steam temperature

As the initial steam pressure increases, the humidity of the steam at the turbine outlet increases, which is illustrated by the graphs on the iS diagram (see Fig. 2.3).

Р1 > Р1" > Р1"" (t1 = const, P2 = const)

x2< x2" < x2"" (y = 1 – x)

y2 > y2" > y2""

Figure 2.3 – The nature of the change in the final moisture content of steam with an increase in the initial steam pressure.

The presence of steam moisture increases friction losses and reduces internal relative efficiency. and causes droplet erosion of the blades and other elements of the turbine flow path, which leads to their destruction.

The maximum permissible steam humidity (y2add) depends on the length of the blades (ll); For example:

ll ≤ 750…1000 mm y2add ≤ 8…10%

ll ≤ 600 mm y2add ≤ 13%

To reduce the humidity of steam, the temperature should be increased along with an increase in steam pressure, which is illustrated in Figure 2.4.

t1 > t1" > t1"" (P2 = const)

x2 > x2" > x2"" (y = 1 - x)

y2< y2" < y2""

Figure 2.4 – The nature of the change in the final moisture content of steam with an increase in the initial temperature of steam.

The steam temperature is limited by the heat resistance of the steel from which the superheater, pipelines, and turbine elements are made.

It is possible to use steels of 4 classes:

1) carbon and manganese steels (with maximum temperature tpr ≤ 450...500°C);

2) chrome-molybdenum and chrome-molybdenum-vanadium steels of the pearlitic class (tpr ≤ 570...585°C);

3) high-chromium steels of the martensitic-ferritic class (tpr ≤ 600...630°C);

4) stainless chromium-nickel steels of the austenitic class (tpr ≤ 650...700°C).

When moving from one class of steel to another, the cost of equipment increases sharply.

Steel grade

Relative cost

On at this stage from an economic point of view, it is advisable to use pearlitic steel with an operating temperature tr ≤ 540°C (565°C). Steels of the martensitic-ferritic and austenitic class lead to a sharp increase in the cost of equipment.

It should also be noted the influence of the initial steam temperature on thermal efficiency. cycle of a steam turbine plant. An increase in steam temperature leads to an increase in thermal efficiency:

Most often in modern energy, traditional and non-traditional energy are distinguished.

Traditional energy is mainly divided into electric power and thermal power.

The most convenient type of energy is electrical, which can be considered the basis of civilization. The conversion of primary energy into electrical energy is carried out at power plants.

Our country produces and consumes a huge amount of electricity. It is almost entirely produced by three main types of power plants: thermal, nuclear and hydroelectric power plants.

Approximately 70% of the world's electricity is generated by thermal power plants. They are divided into condensing thermal power plants (CHPs), which produce only electricity, and combined heat and power plants (CHPs), which produce electricity and heat.

In Russia, about 75% of energy is produced at thermal power plants. Thermal power plants are built in areas of fuel production or in areas of energy consumption. It is profitable to build hydroelectric power stations on deep mountain rivers. Therefore, the largest hydroelectric power stations were built on Siberian rivers. Yenisei, Angara. But cascades of hydroelectric power stations have also been built on lowland rivers: the Volga and Kama.

Nuclear power plants are built in areas where a lot of energy is consumed and other energy resources are scarce (in the western part of the country).

The main type of power plants in Russia are thermal power plants (TPP). These installations generate approximately 67% of Russia's electricity. Their placement is influenced by fuel and consumer factors. The most powerful power plants are located in places where fuel is produced. Thermal power plants using high-calorie, transportable fuel are aimed at consumers.

Fig.1. Schematic diagram of a thermal power plant

The schematic diagram of the thermal power plant is shown in Fig. 1. It is worth keeping in mind that its design may include several circuits - the coolant from the fuel reactor may not go directly to the turbine, but give up its heat in the heat exchanger to the coolant of the next circuit, which can already flow to the turbine, or can then transfer its energy to the next one contour. Also, any power plant is equipped with a waste coolant cooling system to bring the coolant temperature to the value required for the recycle. If there is a populated area near the power plant, this is achieved by using the heat from the waste coolant to heat water for home heating or hot water supply, and if not, then the excess heat from the waste coolant is simply released into the atmosphere in cooling towers. Cooling towers are most often used as a condenser for exhaust steam in non-nuclear power plants.

The main equipment of a thermal power plant is a boiler-steam generator, a turbine, a generator, a steam condenser, and a circulation pump.

In a steam generator boiler, when fuel is burned, thermal energy is released, which is converted into water steam energy. In a turbine, the energy of water vapor is converted into mechanical rotational energy. The generator converts mechanical rotational energy into electrical energy. The CHP scheme differs in that, in addition to electrical energy, heat is also generated by removing part of the steam and using it to heat the water supplied to the heating mains.

There are thermal power plants with gas turbine units. The working fluid and them are gas with air. Gas is released during the combustion of organic fuel and mixes with heated air. The gas-air mixture at 750-770°C is fed into a turbine, which rotates the generator. TPPs with gas turbine units are more maneuverable, easy to start, stop, and adjust. But their power is 5-8 times less than steam ones.

The process of generating electricity at thermal power plants can be divided into three cycles: chemical - the combustion process, as a result of which heat is transferred to steam; mechanical - the thermal energy of steam is converted into rotational energy; electrical - mechanical energy is converted into electrical energy.

The overall efficiency of a thermal power plant consists of the product of the efficiency (η) of cycles:

![]()

![]()

The efficiency of an ideal mechanical cycle is determined by the so-called Carnot cycle:

where T 1 and T 2 are the steam temperatures at the inlet and outlet of the steam turbine.

At modern thermal power plants T 1 =550°C (823°K), T 2 =23°C (296°K).

Practically taking into account losses η tes = 36-39%. Due to the more complete use of thermal energy, the efficiency of the thermal power plant = 60-65%.

A nuclear power plant differs from a thermal power plant in that the boiler is replaced by a nuclear reactor. Heat nuclear reaction used to produce steam.

The primary energy at a nuclear power plant is internal nuclear energy, which, during nuclear fission, is released in the form of colossal kinetic energy, which, in turn, is converted into thermal energy. The installation where these transformations take place is called a reactor.

A coolant substance passes through the reactor core, which serves to remove heat (water, inert gases, etc.). The coolant carries heat into the steam generator, giving it to water. The resulting water vapor enters the turbine. The reactor power is regulated using special rods. They are introduced into the core and change the neutron flux, and therefore the intensity of the nuclear reaction.

The natural nuclear fuel of a nuclear power plant is uranium. For biological protection against radiation, a layer of concrete several meters thick is used.

When burning 1 kg of coal you can get 8 kWh of electricity, and with the consumption of 1 kg of nuclear fuel, 23 million kWh of electricity is generated.

For more than 2000 years, humanity has been using the Earth's water energy. Now water energy is used in three types of hydropower plants:

- hydraulic power plants (HPP);

- tidal power plants (TPPs), using the energy of the tides of the seas and oceans;

- pumped storage power plants (PSPPs), which accumulate and use the energy of reservoirs and lakes.

Hydropower resources in the turbine of the power plant are converted into mechanical energy, which is converted into electrical energy in the generator.

Thus, the main sources of energy are solid fuel, oil, gas, water, and the decay energy of uranium nuclei and other radioactive substances.

Course of lectures on the discipline

"Energy supply and energy efficiency of technologies"

Module 1. Energy production. 2

Topic 1. Basic information about thermal power plants. 2

Topic 2. “Main and auxiliary equipment of thermal power plants.” 19

Topic 3. Energy conversion at thermal power plants.. 37

Topic 4 “Nuclear power plants”. 58

Topic 5 “Basic information about hydroelectric power plants.” 72

Module 2. “Energy production and distribution systems.” 85

Topic 6. “Energy resources”. 85

Topic 7 “Basic systems for the production and distribution of energy resources of industrial enterprises.” 94

Module 1. Energy production.

Topic 1. Basic information about thermal power plants.

1.1 General information.

1.2 Thermal and technological schemes TPP.

1.3 Layout diagrams of thermal power plants.

General information

Thermal power plant(TPP) - a power plant that generates electrical energy as a result of the conversion of thermal energy released during the combustion of organic fuel. The first thermal power plants appeared at the end of the 19th century and by the mid-70s. In the 20th century, thermal power plants became the main type of power plant in the world. The share of electricity generated by them in Russia is about 80% and about 70% in the world.

Most Russian cities are supplied with electricity from thermal power plants. Often in cities CHP plants are used - combined heat and power plants that produce not only electricity, but also heat in the form hot water or a couple. Despite the higher efficiency, such a system is quite impractical, because, unlike electric cables, the reliability of heating mains is extremely low over long distances, since the efficiency of centralized heat supply is greatly reduced due to a decrease in the temperature of the coolant. It is estimated that when heating mains are more than 20 km long (a typical situation for most cities), installing an electric boiler separately standing house becomes more economically profitable.

In thermal power plants, the chemical energy of the fuel is converted first into thermal energy, then into mechanical energy, and then into electrical energy.

The fuel for such a power plant can be coal, peat, gas, oil shale, and fuel oil. Thermal power plants are divided into condensing power plants (CHPs), designed to generate only electrical energy, and combined heat and power plants (CHPs), which produce, in addition to electricity, thermal energy in the form of hot water and steam. Large CPPs of regional significance are called state district power plants (SDPPs).

Thermal and technological diagrams of thermal power plants

The principal thermal diagram of a thermal power plant shows the main coolant flows associated with the main and auxiliary equipment in the processes of heat conversion for the generation and supply of electricity and heat. In practice, the basic thermal diagram is reduced to a diagram of the steam-water path of a thermal power plant (power unit), the elements of which are usually represented in conventional images.

Simplified (principal) thermal diagram of a coal-fired thermal power plant, is presented in Figure 1. Coal is supplied to the fuel bunker 1, and from it to the crushing plant 2, where it turns into dust. Coal dust enters the furnace of a steam generator (steam boiler) 3, which has a system of tubes in which chemically purified water, called feed water, circulates. In the boiler, water is heated, evaporated, and the resulting saturated steam is brought to a temperature of 400-650°C and, under a pressure of 3-25 MPa, enters steam turbine 4 through a steam line. The parameters of superheated steam (temperature and pressure at the turbine inlet) depend on the power of the units .

Complete thermal diagram differs from the fundamental one in that it completely displays equipment, pipelines, shut-off, control and protective valves. The complete thermal diagram of a power unit consists of diagrams of individual components, including a general station unit (spare condensate tanks with transfer pumps, heating network replenishment, raw water heating, etc.). Auxiliary pipelines include bypass, drainage, drain, auxiliary, and suction of the steam-air mixture.

Figure 1 - Simplified thermal diagram of a thermal power plant and appearance of a steam turbine

Thermal CESs have low efficiency (30 - 40%), since most of the energy is lost with flue gases and condenser cooling water. CPPs running on fossil fuels are usually built near fuel extraction sites.

A CHP plant differs from a CPP by having a special heating turbine installed on it with intermediate steam extractions or with back pressure. In such plants, the heat of the exhaust steam is partially or even completely used for heat supply, as a result of which water losses from cooling water are reduced or absent altogether (in plants with back-pressure turbogenerators). However, the share of steam energy converted into electricity, with the same initial parameters, in installations with heating turbines is lower than in installations with condensing turbines. At a thermal power plant, one part of the steam is completely used in the turbine to generate electricity in the generator 5 and then enters the condenser 6, and the other, which has a higher temperature and pressure (dashed line in the figure), is taken from the intermediate stage of the turbine and is used for heat supply. The condensate is supplied by pump 7 through the deaerator 8 and then by the feed pump 9 to the steam generator. The amount of steam taken depends on the thermal energy needs of enterprises.

The efficiency of thermal power plants reaches 60-70%.

Such stations are usually built near consumers- industrial enterprises or residential areas. Most often they run on imported fuel.

The considered thermal power plants, by the type of the main thermal unit (steam turbine), are classified as steam turbine stations. Thermal stations with gas turbine (GTU), combined cycle gas turbine (CCGT) and diesel units have become significantly less widespread.

The most economical are large thermal steam turbine power plants. In a steam boiler, over 90% of the energy released by the fuel is transferred to steam. In the turbine, the kinetic energy of the steam jets is transferred to the rotor (Figure 1). The turbine shaft is rigidly connected to the generator shaft. Modern steam turbines for thermal power plants are high-speed (3000 rpm), highly economical machines with a long service life. Their single-shaft power reaches 1200 MW, and this is not the limit. Such machines are always multi-stage, that is, they usually have several dozen disks with working blades and the same number, in front of each disk, of groups of nozzles through which a stream of steam flows. At the same time, the pressure and temperature of the steam gradually decrease.

High-power CPPs using organic fuel are currently being built mainly for high initial steam parameters and low final pressure (deep vacuum). This makes it possible to reduce heat consumption per unit of generated electricity, since the higher the initial parameters p 0 and T 0 in front of the turbine and below the final steam pressure R k, the higher the efficiency of the installation. Therefore, the steam entering the turbine is brought to high parameters: temperature - up to 650 ° C and pressure - up to 25 MPa.

Figure 2 shows typical thermal diagrams of CESs running on fossil fuels. According to the diagram in Figure 2a, heat is supplied to the cycle only when steam is generated and heated to the selected superheat temperature t lane;according to the diagram in Figure 2b, along with the transfer of heat under these conditions, heat is supplied to the steam after it has worked in the high pressure part of the turbine.

The first circuit is called a circuit without intermediate overheating, the second - a circuit with intermediate superheating of steam. As is known from the thermodynamics course, the thermal efficiency of the second scheme is higher with the same initial and final parameters and the correct choice of intermediate overheating parameters.

In both schemes, steam from steam boiler 1 is sent to turbine 2, located on the same shaft as electric generator 3. The exhaust steam is condensed in condenser 4, cooled by process water circulating in the tubes. Turbine condensate by condensate pump 5 through regenerative heaters 6 it is supplied to the deaerator 8.

Figure 2 - Typical thermal diagrams of steam turbine condensing plants using organic fuel without intermediate superheating of steam (a) and with intermediate superheating (b)

The deaerator is used to remove gases dissolved in it from water; at the same time, in it, just like in regenerative heaters, the feed water is heated by steam, taken for this purpose from the turbine outlet. Deaeration of water is carried out in order to bring the content of oxygen and carbon dioxide in it to acceptable values and thereby reduce the rate of corrosion in the water and steam paths. At the same time, a deaerator may be absent in a number of thermal circuits of IES.

Deaerated water feed pump 9 through heaters 10 it is supplied to the boiler plant. The condensate of the heating steam formed in the heaters 10 is passed cascade into the deaerator 8, and the condensate of the heating steam of the heaters 6 is supplied drain pump 7 in line, through which condensate flows from condenser 4.

The described thermal schemes are largely typical and change slightly with increasing unit power and initial steam parameters.

The deaerator and feed pump divide the regenerative heating circuit into groups HPH (high pressure heater) and LPH (low pressure heater). PVD Group As a rule, it consists of two or three heaters with cascade drainage down to the deaerator. The deaerator is fed with steam of the same extraction as the upstream HPH. This scheme for switching on a deaerator using steam is widespread. Since a constant steam pressure is maintained in the deaerator, and the pressure in the extraction is reduced in proportion to the decrease in steam flow to the turbine, this scheme creates a pressure reserve for the extraction, which is realized in the upstream HPH. HDPE Group consists of three to five regenerative and two to three auxiliary heaters. If there is an evaporative installation (cooling tower), the evaporator condenser is switched on between the HDPE.

Technological diagram of thermal power plant, operating on coal, is shown in Figure 3. It is a complex complex of interconnected paths and systems: dust preparation system; fuel supply and ignition system (fuel path); slag and ash removal system; gas-air path; a steam-water path system, including a steam-water boiler and a turbine unit; a system for preparing and supplying additional water to replenish losses of feed water; technical water supply system providing steam cooling; network water heating system; an electrical power system, including a synchronous generator, step-up transformer, high-voltage switchgear, etc.

Figure 3 - Process diagram of a pulverized coal power plant

Figure 3 - Process diagram of a pulverized coal power plant

Below is given a brief description of main systems and paths of the technological scheme of a coal-fired thermal power plant.

1. Dust preparation system. Fuel path. Delivery of solid fuel is carried out by railway in special gondola cars 1. Gondola cars with coal are weighed on railway scales. IN winter time gondola cars with coal are passed through a defrosting greenhouse, in which the walls of the gondola car are heated with heated air. Next, the gondola car is pushed into the unloading device - car dumper 2, in which it is rotated around the longitudinal axis at an angle of about 180 0; coal is dumped onto grates covering the receiving hoppers. Coal from the bunkers is supplied by feeders to the conveyor 4, through which it is supplied either to the coal warehouse 4, or through the crushing compartment 5 to the raw coal bunkers of the boiler room 6, to which it can also be delivered from the coal warehouse.

From the crushing plant, fuel enters the raw coal bunker 6, and from there through feeders into the pulverized coal mills 7. Coal dust is pneumatically transported through the separator 8 and the cyclone 9 into the coal dust bunker 10, and from there it is supplied to the burners by feeders 11. Air from the cyclone is sucked in by the mill fan 12 and supplied to the combustion chamber of the boiler 13.

This entire fuel line, together with the coal warehouse, belongs to fuel supply system, which is serviced by the personnel of the fuel and transport workshop of the thermal power plant.

Pulverized coal boilers also necessarily have a starting fuel, usually fuel oil. Fuel oil is delivered in railway tanks, in which it is heated with steam before being discharged. Using the first and second lift pumps, it is supplied to the fuel oil nozzles. The starting fuel can also be natural gas supplied from the gas pipeline through the gas control point to the gas burners.

At thermal power plants that burn gas and oil fuel, the fuel economy is significantly simplified compared to pulverized coal thermal power plants, the coal warehouse, crushing department, conveyor system, raw coal and dust bunker, as well as ash collection and ash removal systems are eliminated.

2. Gas-air path. Slag and ash removal system. The air required for combustion is supplied to the air heaters of the steam boiler by a blower fan 14. Air is usually taken from the top of the boiler room and (for high-capacity steam boilers) from outside the boiler room.

The gases formed during combustion in the combustion chamber, after exiting it, pass successively through the gas ducts of the boiler installation, where in the steam superheater (primary and secondary, if a cycle with intermediate superheating of steam is carried out) and the water economizer, heat is transferred to the working fluid, and the air heater is supplied to the steam boiler air. Then, in ash collectors (electric precipitators) 15, the gases are purified from fly ash and released into the atmosphere through a chimney 17 using smoke exhausters 16.

Slag and ash falling under the combustion chamber, air heater and ash collectors are washed off with water and flow through channels to 33 lag pumps, which pump them into ash dumps.

3. Steam-water path. Superheated steam from steam boiler 13 flows through steam lines and a nozzle system to turbine 22.

Condensate from turbine condenser 23 is supplied by condensate pumps 24 through low-pressure regenerative heaters 18 into a deaerator 20, in which water is brought to a boil; at the same time, it is freed from the aggressive gases O 2 and CO 2 dissolved in it, which prevents corrosion in the steam-water path. From the deaerator, water is supplied by feed pumps 21 through high-pressure heaters 19 to the boiler economizer, providing intermediate superheating of the steam and significantly increasing the efficiency of the thermal power plant.

The steam-water path of a thermal power plant is the most complex and responsible, because in this path the highest metal temperatures and the highest steam and water pressures occur.

To ensure the functioning of the steam-water path, a system for preparing and supplying additional water to replenish losses of the working fluid, as well as a technical water supply system for thermal power plants to supply cooling water to the turbine condenser are required.

4. System for preparing and supplying additional water. Additional water is obtained as a result of chemical purification of raw water, carried out in special ion exchange filters for chemical water treatment.

Losses of steam and condensate due to leaks in the steam-water path are replenished in this scheme with chemically desalted water, which is supplied from the demineralized water tank by a transfer pump to the condensate line behind the turbine condenser.

Devices for chemical treatment of additional water are located in chemical shop 28 (chemical water treatment shop).

5. Steam cooling system. Cooling water supplied to the condenser from the receiving water supply well 26 circulation pumps 25 . The cooling water heated in the condenser is discharged into a collecting well 27 of the same water source at a certain distance from the point of intake, sufficient so that the heated water does not mix with the taken water.

In many technological schemes of thermal power plants, cooling water is pumped through the condenser tubes by circulation pumps 25 and then enters the cooling tower (cooling tower), where due to evaporation the water is cooled by the same temperature difference by which it was heated in the condenser. Water supply systems with cooling towers are used mainly at thermal power plants. The IES uses a water supply system with cooling ponds. When evaporative cooling of water occurs, the evaporation is approximately equal to the amount of steam condensing in the turbine condensers. Therefore, water supply systems need to be recharged, usually with river water.

6. System of network water heating units. In the diagrams a small network heating installation can be provided for district heating of the power plant and the adjacent village. The network heater 29 of this installation receives steam from the turbine extractions, the condensate is discharged through line 31. The network water is supplied to the heater and discharged from it through pipelines 30.

7. Electric power system. An electric generator rotated by a steam turbine produces alternating electric current, which goes through a step-up transformer to the busbars of the open switchgear (OSD) of the thermal power plant. The buses of the auxiliary system are also connected to the generator terminals through an auxiliary transformer. Thus, the power unit’s auxiliary consumers (electric motors of auxiliary units – pumps, fans, mills, etc.) are powered by the power unit’s generator. To supply electricity to electric motors, lighting devices and devices of the power plant, there is an auxiliary electrical distribution device 32.

IN special cases(emergency situations, load shedding, start-up and shutdowns) power supply for auxiliary needs is provided through the backup busbar transformer of the outdoor switchgear. Reliable power supply to the electric motor of auxiliary units ensures the reliable operation of power units and thermal power plants as a whole. Disruption of the power supply for own needs leads to failures and accidents.