Swedish brick oven. Do-it-yourself “Swedish” stove: drawings and order

close ×

Stoves have long been used by residents of rural regions for heating and cooking. Then the tradition of building in a house migrated to the city. Nowadays, such designs are mainly used in dachas or private homes. The classic Russian stove is being replaced by another stove - the Swedish stove, which is superior to Russian and Dutch stoves in numerous respects. For example, a stove that came from Sweden is distinguished by its compact dimensions, economical use of fuel, greater heat output, etc.

The Swedish stove is used not only for heating the room, but can also act as a mini-kitchen. To do this, you need to install a hob on a folded platform or equip an oven. This multifunctional design allows you to both cook and heat the entire house.

The designers of the Swedish brick kiln took into account the peculiarities of the Scandinavian climate, which is characterized by dampness. In fairly cold conditions, it was necessary to quickly warm the house, dry clothes, and prepare food. Therefore, the design has a special partition that allows the stove to be used in two rooms at once. This is the main difference between a Swedish oven and a Dutch oven.

In addition to the above-mentioned advantages, the design has a number of positive qualities, among which it is worth noting such as:

- The firebox, made in the form of a bell, ensures proper combustion of fuel, long-term maintenance of heat and smoldering of firewood.

- You can install an additional hob on a Swedish stove with a stove.

- The stove is installed between the kitchen and living room, which allows you to warm the room while cooking.

- You can install a water circuit on the stove, which will allow you to use it for heating a house or bathhouse.

- High efficiency of fuel combustion. It is allowed to use firewood, reeds, and small wood. These types of fuel have increased heat transfer, so your home will always be warm and dry.

- The Swede warms up within 10-15 minutes after the fuel is ignited. In order to retain heat for as long as possible, it is necessary to close the valve tightly.

A Swedish stove for a country house is the most suitable option for heating and cooking food and heating water. While there are a large number of advantages, it is necessary to note the presence of certain disadvantages:

- First, you need to carefully select the material. It must be of high quality. Fireclay brick is not suitable, which affects the duration of heat retention.

- Secondly, construction must be approached carefully, involving specialists who will be able to correct mistakes at the bricklaying stage.

- Thirdly, you should not skimp on specialists who will help you start the heating system. Otherwise, the oven will not function as it should.

- Fourthly, it gets damp quickly, so the stove must be constantly in use. If this does not happen, then the structure must be thoroughly dried before heating.

Characteristics

Unlike the Dutch, the Swede has compact dimensions:

- Height varies from 2030 to 2170 mm.

- The width can be between 880-885 mm.

- Height - from 1010 to 1020 mm.

This small Swedish stove is very easy to assemble with your own hands and is capable of heating a room of up to 30-35 m2.

There are several types of Swedish stoves, which differ in the nature of their assembly and functional purpose. Furnaces are divided into the following groups:

- A Swedish fireplace with a hob that faces the street. Inside the room there is a firebox and a fireplace portal. This type is usually installed in the living room.

- Swedish stoves with deck chairs. Suitable for cold regions and small rooms where there is not enough space. The lounger can act as a bed.

- Stoves with hob and oven. Such structures are installed between the kitchen and the room.

Before you build a brick stove with your own hands, you need to find out the dimensions of the house and draw up a drawing indicating the location of the stove on it. This will save time on redesigning the design.

For country houses, it is best to choose a Swede that will not be equipped with a heating system.

In winter, people rarely come to their dacha, so there is no need to install an expensive structure. But for a country house, it is better to install a stove model that will allow you to both cook and heat the entire house.

Design and operating principle

The Swedish heating and cooking stove was made on the basis of the Dutch one, which did not have an oven, hob, place for drying clothes and heating water.

The principle of operation of the Swede, without reference to models, is one - channel. The firebox oven is located on the side, allowing heat to be transferred directly into the room. When the wood begins to give off heat, then it gradually begins to heat the oven and the side, and only then goes down.

The upper part of the Swedish stove heats up very quickly, due to the fact that the heat transfer channels are located at the back of the panel.

The efficiency of the Swedish model significantly exceeds the productivity of the Dutch one. For example, if a Dutch woman gives off about 2.5 thousand kilocalories of heat per hour, then a Swede gives off 3.5 thousand kcal. To do this, it is enough to put several portions of firewood into the firebox during the day, and the heat in the house will remain for 24 hours.

High-level economics and efficiency in a Swedish-assembled stove are ensured thanks to a rather complex smoke exhaust system. As a result, it is simply rational to use heat in winter and summer, setting a different type of construction for each season.

If the stove is provided with a deck, then the heat transfer channels must be installed in a horizontal position. A special valve is installed next to the channels, which helps regulate the heat supply in summer and winter. The valve can be rotated in a horizontal or vertical position, depending on the season. In horizontal mode, the heat will go directly to the sunbed, and in summer - into the chimney.

The design of the Swedish stoves may differ, depending on the model, but the following elements are required in the stove:

- An oven that is intended for heating. The oven is made in the form of a hood, thanks to which the flame from the fuel does not touch its walls, but is immediately transferred to the heating elements. The so-called flue gases go down, so the stove is heated from the floor.

- The upper niche, which is heated by the heat of the first or second level. This space is usually used to dry clothes.

- A niche above the stove, which is made above the hob. You can put cooked food here to keep it hot in the morning.

- Smoke circulation, made in the form of a special flow window. This should be done from the bottom of the oven.

Fuel types

The structure is built in a house for more than one year, so only high-quality bricks must be used for laying the stove, and heating must be carried out only with approved materials. The efficiency and amount of heat generated depends on this. Different types of fuel provide different amounts of heat, and this must be taken into account when choosing how to heat a room. The most common types of fuel for Swedes include:

- Wood of different species. It is worth considering that birch, oak, beech, and maple can provide much more heat than pine, aspen or alder. Firewood must be dried so that it produces a lot of ash and not smoke.

- Peat, which can be pressed, lump, carved, milled. It is best to use pressed peat, the briquettes of which are highly dense. As a result, a few pieces are enough to maintain heat for a long time. In terms of heat transfer, peat is close to wood. The amount of thermal mass released depends directly on how correctly the peat was dried and pressed.

- Coal, for which a special grate must be placed on the Swedish stove. Its elements must be heated by coal, which gradually burns.

Do-it-yourself Swedish oven

Before assembling the “Swede”, it is necessary to draw up an exact diagram of the order of the stove, indicate the places where the oven, hob, chimney, and air ducts will be located. The easiest way is to assemble a cooking-heating stove yourself, which will have all the necessary components. The hob and oven are made of glass, and the oven door is made of glass.

Materials

To assemble a Swede with your own hands, you need to stock up on the following materials:

- Fireclay brick, which is made from refractory clay. You cannot use ordinary brick; it is not able to withstand high temperatures.

- Clay used to hold bricks together during laying.

- Metal flaps, latches, doors that help in the full operation of the Swede.

- Finishing materials - plaster, lime, clay.

Tools

To lay the swede in order, you will also need special tools, which include a trowel, a bayonet shovel, a plumb line, a hammer, a level, and a container for preparing the solution.

Tools required for masonry

Tools required for masonry Foundation

How to fold the stove when all the preparations are done? First of all, you need to make markings for the foundation, on which the stove will then be placed. The marking should be 10-15 centimeters larger than the base of the stove. Then you need to dig a hole, at the bottom of which lay a mixture made from sand and water. The width of the layer should not be more than 20 centimeters. Crushed stone is poured on top of the sand, which must be compacted well, and formwork made of wooden boards must be placed.

They are covered with plastic film, on top of which a concrete solution must be poured. The thickness of this layer should not be less than 15 cm. Reinforcement must be placed in the cement that has not yet hardened, pressed into the mortar and filled with cement again.

The next step will be to install a mesh of reinforcement, but only when the first ball of mortar becomes solid. The second layer must be leveled and wait for it to harden. In total, these two phases will take three to four weeks. When they pass, the Swede's serial laying begins.

We put the stove, stove, oven

While the foundation is drying, you need to take care of the fuel part - stoves, fireboxes, ovens. The thickness of the slab should not be less than 710 by 410 mm. The dimensions of the firebox can be as follows:

- Height varies between 281 by 330 mm;

- The width is 305 by 356 mm;

- The depth is 406 by 506 mm.

The oven will have almost the same dimensions as the firebox. The oven depth will be 281 by 305 mm, width - 330 by 381 mm, depth - 456 by 506 mm, the thickness of each oven wall will be, on average, from 4 to 6 mm. The walls should not be thin so as not to burn quickly, but they should not be made thick either, otherwise the oven will take a long time to heat up.

For the firebox, you need to take a cast door that has a “whisker” and is embedded in the masonry. The “whiskers” are installed independently if you weld annealed steel wire at the corners of the door frame. You will need two pieces that will be parallel to each other. Then the “whiskers” must be spread apart, giving the wire a V shape. These elements must also be embedded in the wall, additionally secured with a steel corner.

Fire door with welded “whiskers”

Fire door with welded “whiskers” Order

The new stage of construction of the Swedish stove will be quite long in order to correctly arrange the bricks.

The sequential installation of the stove looks like this:

- The base is laid out in the form of a square, each side of which is 1.1 m. The top should be exactly one brick below the floor level.

- Then the first continuous row of bricks is created.

- The second row will also be solid, but in place of the fireplace you need to install a grate.

- The third row is laid out with bricks, creating a vertical channel and a space allocated for the oven. After this, you need to mount the doors and build a firebox for the fireplace.

- The fourth row - bricks are simply laid out.

- Fifth row - at the same time as the laying, a grate must be installed.

- The sixth row is to create an overlap between the oven and the vertical channel.

- Seventh row - you need to install two strips of metal.

- The eighth and ninth rows are ordinary brickwork.

- Tenth row - you need to make a niche intended for cleaning the fireplace; a hob is installed.

- Eleventh row - a niche is made for the hob, the holes are blocked.

- Rows 13-15 - a mantelpiece is created, so the bricks need to be pushed forward a little. In 13-14 rows you need to lay bricks that will be cut obliquely. They should be positioned towards the front plane of the fireplace.

- Row 16 - completing a niche for the hob.

- Rows 17-18 - laid out with bricks without additional mounting elements.

- Rows 19-20 - a chimney is formed.

- Rows 21-23 - doors are created for cleaning channels.

- Row 24 - you need to install a damper for the fireplace.

- Row 25 - the valve for the furnace is installed.

- Row 26 - the vertical channel must be connected to the chimney.

- Rows 27-28 - creating the longitudinal walls of the channel that will pass above the fireplace.

- Rows 29-30 - solid brickwork.

- Row 31 - a common valve is installed.

- Row 32 - formation of the Swedish oven pipe.

Furnace arrangement diagram

Furnace arrangement diagram Important nuances

The foot of the oven - usually the first two rows - should be wide. This is achieved through seams with a width of 6 to 13 mm. This way you can get a pedestal that has the shape of a protrusion. You should not make the ledge wider so that the foot does not turn out awkward.

Before laying, each brick must be immersed in water and rinsed. This will ensure a strong masonry. The brick should be in the water for no more than 15 seconds so that the material does not take on water. If it penetrates into the masonry, then the structure will fall apart.

The master must pay special attention to the combustion chamber in order to burn fuel efficiently. It is made of fireclay bricks, which have a light yellow color. The mortar for masonry must be prepared using fireclay clay. It is not recommended to use fireclay and red bricks together, or stack them end to end. There should be a distance of 6 mm between different materials. For the combustion part, which starts from the third row, fireclay should be used. Considering the high cost of the material, you can line the inside of the firebox with such bricks.

Bricks with rounded corners are used in the chimney to reduce resistance to gas flow and turbulence. The chimney should be made with a fluff, raised 60 cm above the roof.

This design has its name for a reason. She is indeed of Swedish descent. The most common legend says that the Shvedka construction technology came to Russian territory under Peter the Great, having been told by captured Swedes.

Various oven options " Swede»

The oven has been developed Swede“was back in the 18th century. In those days, people needed an economical heating design with high efficiency, ideal for the harsh Swedish climate. The “Dutch” systems that became widespread could not cope with the tasks.

In fact, the new heating and cooking stove has become an improved version of the same Dutch stove. It had an enlarged firebox part, which was placed in the oven of a simple-designed kitchen stove.

Features of the Swede

The main difference of this design is the presence of a heating panel, which is located in the rear part. It contains gas ducts, the direction of which can be horizontal or vertical.

The video shows the process of making a Shvedka stove with your own hands

Passing through a curved channel, the smoke heats up the stove structure, which, in turn, distributes heat throughout the room. Such a system is characterized by high rates of economy and efficiency, because if in a conventional furnace heat simply goes vertically into the pipe, here it passes through internal channels, warming up the structure well.

The main advantages of such a furnace:

- Compact dimensions. A standard “Swedish” takes up only 1 m2. Such a stove is capable of heating a house with an area of 30 m2.

The stove is very compact and rarely takes up more than 1 m2 in area

Advice! For more efficient heating of the house, it is advisable to place the stove in two rooms so that the combustion part is located in the kitchen, and the location of the panel is in the living room or bedroom.

- High efficiency. The effectiveness of this design is determined by the presence of a complex chimney system, thanks to which the rational use of heat occurs. Such stoves allow you to create two or three heating options: for summer, winter and autumn. For example, in the summer you can comfortably cook on such a stove, without any increase in the temperature in the room.

Oven options

There are several options for this stove, each of which has its own function:

- The simplest of them is without an oven, which in addition to the firebox is equipped with a cast iron hob. To ventilate the structure, a hood located above the stove is used.

Advice! To prevent the smell of cooking food from entering the room, the oven is equipped with glass doors.

- A Swedish oven with an oven and stove may also have a special niche where you can dry fruits and vegetables, mushrooms, as well as clothes and shoes.

- The Swedish stove is an analogue of the Russian stove and until relatively recently it was quite common. Now such designs have been replaced by more compact classic versions. However, the positive effect of such stoves on colds is widely known. Our ancestors believed that if you sleep on a well-heated stove, the disease will go away.

- With a fireplace. This stove is perfect for a country house. This design is most often located between the kitchen and living room. In this case, the fireplace part of the stove is located on the living room side, and the hob is located on the kitchen side.

Regarding the construction of the shield, such furnaces are also divided into several types:

- In the case of a horizontal shield, the structure is heated evenly. However, to clean such a system, a large number of cleaning holes equipped with doors is necessary, which makes such a structure more difficult to construct and expensive.

- In the case of a vertical arrangement of gas ducts, such a stove may have only one cleaning hatch. Since most often such stoves are located between two rooms, one of them will warm up faster than the other. This is explained by the fact that in the first channel, located on the furnace side, the temperature will be significantly higher than in the third, where somewhat cooled gases are discharged.

- Swede with bell-type firebox. This option has the advantages of both systems described above. In this case, the oven heats up evenly, and the structure itself requires only one cleaning window. Another plus is that the construction of such a furnace requires less brick. In addition, this design cools down relatively slower.

Features of the construction of Swedes with a fireplace

Since the most modern and interesting option is the one with a fireplace, the features of its construction should be considered in more detail. First of all, the order of the Swedish stove is necessary, focusing on which you can build this stove without any problems.

So, the Swede is built with your own hands according to the following scheme:

- The first row is laid completely solid.

- The second row should provide for the installation of a grille.

- From the third row, the formation of the ash pan begins. The door is installed. Next, a vertical channel is built parallel to the oven space.

- To remove ash, two doors are installed, after which the firebox should be laid out.

- The fourth row completely duplicates the previous one.

- In the fifth row, a seat for the grate begins to form.

- The sixth row involves building an overlap between the oven and the vertical channel. The firebox door is also installed here.

Advice! The bricks between the oven and the firebox should be installed on edge.

- Before laying the seventh row, two metal strips must be laid.

- The next two rows are laid out in the same way as the seventh. After laying the ninth row, two steel strips should be laid above the oven.

- Starting from the 10th row, a place is built for cleaning the fireplace. Also from this row is a place for installing a hob.

- Row 11 is distinguished by the formation of a cooking niche.

- In the 12th row, it is necessary to place bricks cut at an angle in the front wall of the fireplace.

- The 13th row is laid out in the same way as the previous one.

- To create a mantelpiece, in this row the bricks extend 25 mm around the entire perimeter of the stove.

- In the 15th row, the bricks are pushed out another 25 mm.

- The installation of the cooking niche is completed by installing three strips of metal.

- The 17th and 18th rows do not differ from each other and are laid out in accordance with the order.

- The 19th row is distinguished by the formation of chimneys. To do this, lay bricks cut from both sides between the fireplace and vertical channels.

- Next, three rows are laid out equally, forming doors intended for cleaning the channels. In this case, the partition present between the fireplace and the vertical channel should gradually shift to the left.

- The fireplace damper is installed when laying the 24th row, and the stove damper - when laying the 25th.

- The cleaning door is installed in the 26th row, in the same row the chimney is connected to the vertical duct.

- Next, the rows are laid out relative to the order. The 29th row is continuous and forms a chimney opening. The laying of the pipe itself begins from the 32nd row.

Advice! Brick should be soaked before laying. It must be free of chips and cracks.

Conclusion

The Shvedka stove is a high-efficiency heating structure that has not undergone significant design changes for several centuries. In addition, the Shvedka is very compact, which makes it ideal for heating country houses. If you wish, you can build it yourself.

If you need to build a cooking and heating device at home, we recommend paying attention to the stove called “Swedge”. This version of the stove is characterized by its compact size, ease of construction, and quick heating to the desired temperature. We will learn further about how to make a stove with your own hands.

Photos of ovens by hand - the history of the creation of the Shvedka oven

The design features of the Shvedka stove allow it to be placed in the wall between the kitchen and any other room. This way, you can quickly heat up the kitchen while still cooking. Additional heat is directed to warm the adjacent room. Additionally, the stove can be equipped with a bench or fireplace.

The appearance of modern Swedish stoves can be distinguished by both roughness and decorative delicate patterns. Some purchased models have the shape of a cabinet and are installed ready-made in the room.

According to legend, the Shvedka stove originated in Russia during the reign of Peter the Great. Thus, the Swedes brought this version of the stove. According to other sources, the stove was developed by the Swedes and was built much later. This version of the stove is very similar to the Dutch oven, however, the cooking surface here is wider, and the stove has a wall, thanks to which it is able to heat two rooms at once.

The original version of the Swedish stove was a stove made of brick or a combination of this material with metal, stone, etc. Most often, in Sweden, fireclay bricks, which have high fire-resistant properties, were used to make stoves.

The operating principle of the Swedish oven is based on a combination of several devices. First of all, the oven performs the function of an oven; various types of dishes and pastries are perfectly baked in it. For this purpose, the initial heat that is released during the combustion process is used.

The firebox in a Swedish stove has the shape of a bell, thanks to which it is possible to burn the fuel chemically. A steel oven cannot be directly exposed to flame. It heats up when the first fuel burns. When you open the oven door, after just a few minutes from the moment the oven is fired, the oven heats up. In this case, the smoke is at the bottom, and the oven is heated using gases.

The upper part of the stove has the shape of a niche, it is spacious, and is heated using the first and second heat, as well as smoldering coals. It contains a rope for drying clothes or clothes. Overnight, the clothes dry completely.

The niche located on top of the stove is closed with a special lid. It is used to reheat yesterday's food. Arranging a heat in the space between the firebox and the smoke circulation element is a rather expensive process. Therefore, the Swedish oven is equipped with only a transfer window, which is located under the lower part of the oven.

Heat accumulation in the stove is carried out in relation to duct technology. To warm up the device, the second heat and residual heat from smoldering coal are used. The channels in the stove are located vertically. The lower part of the oven warms up worse than the upper part. This factor should be taken into account when using different types of fuel. It is possible to arrange a horizontal smoke circulation. In this case, the stove generates more heat, but you need to work hard to clean it. In relation to the individual preferences of the owners, the duration and design features of the duct chimney changes.

Another element of the Swedish oven is the second oven. This part of the furnace is located in an adjacent room. It can also contain a fireplace or an equipped bed. Please note that a Swedish lounger or bed is distinguished by certain features of its arrangement. The length of the berth is no more than six feet, and the width is no more than 2.5. A bed is arranged above the lounger, while the lower part is equipped with heating. Under the bed there were also drawers containing linen.

The Swedish stove has a simple design, high efficiency, and affordable cost. The heat output of such a stove is much higher than that of a Dutch stove, while the amount of materials for its construction is much less. In addition, this version of the oven allows you to cook food and dry things in it. With the right approach, it is possible to obtain a high-quality device for heating two rooms at once.

Drawings of stoves by hand: construction of a Swedish stove

In order to correctly build a Swedish stove, it is necessary to adhere to the previously developed drawings and dimensions of this structure. The quality of the resulting heating item is determined primarily by the size of the structure:

We suggest you familiarize yourself with the optimal dimensions of each stove part:

- the size of the plate is 71x41 cm;

- firebox height from 28 to 33 cm, width 32-38 cm, depth 45-50 cm;

- the height, width and depth of the oven are 30x33x50;

- the thickness of the steel from which the oven door is constructed is 0.5 cm;

- the interval between the grate and the nearest wall is about a third of a brick or a whole brick.

These values are approximate and range from 5-10 cm. One of the most important factors is the thickness of the oven walls. If you use thin roofing iron to make an oven, it will heat up quickly and cool down quickly. In this case, it will be impossible to get quality prepared food. The oven and stove are made from steel or a material that does not conduct heat well. The dishes are heated through the burners.

Strictly adhere not only to the specified dimensions of the oven, but also to the proportional relationship between all elements. For example, when constructing a firebox of minimal size, the depth of the furnace will also be minimal. Otherwise, the level of efficiency will significantly decrease.

The oven is washed using gases in all directions. Therefore, a gap must be created between the back wall and the wall of the firebox, the minimum value of which is a quarter of the brick. The depth of the oven is also adjusted according to the previously described parameters. The oven can be located near the firebox if there is insulating material in the form of asbestos or vermiculite between them.

Particular attention should be paid to the combustion door. Since the furnace is subjected to constant thermal loads, this part quickly fails. Therefore, it is recommended to make a cast version of the door, which is walled up in the brickwork. To make a mustache, it is enough to attach a wire about 5 cm long and up to 5 mm in diameter to the door. Wire mustaches are also walled up to better hold the door. An additional steel strip provides better fixation of the material.

Do-it-yourself oven photo:

Quite a lot of difficulties arise in the process of laying a Swedish stove. First of all, before starting work, you need to study the drawings for the stove yourself, according to which the masonry is schematically performed. A Swedish stove produces a large amount of heat, so the floor on which it will be installed must be well-insulated. The best option for thermal insulation is to use basalt cardboard, which is laid in several layers. For work, sheets 0.5 cm thick are used. The middle sheet should have a foil coating with basalt microfiber. Thus, the heat will be reflected into the room.

Next, the base is made. To lay the first two rows of the stove, an interval is observed with additional widening of the seams. Thus, a part is obtained in the form of a pedestal protrusion. Please note that the maximum seam width is 1.3 cm.

Before laying bricks, it is immersed in water for several minutes. Thus, the quality of the masonry increases. Otherwise, dry brick begins to quickly absorb moisture from the mortar, reducing its strength. Keeping a brick in water for too long also negatively affects its quality. Therefore, the brick should be moderately moistened. Marl is used to make masonry mortar. Some oven options are made using ordinary clay. The bricks of the stoves are placed by hand on the mortar previously prepared in small portions.

In order to obtain a high level of efficiency and efficiently burn fuel with maximum heat release, the combustion part should be properly equipped. The temperature inside the firebox should be high, due to this heat is released and the oven heats up. This furnace element is made of light yellow fireclay bricks. Fireclay clay is used to make masonry mortar. Please note that ordinary red brick and its fireclay version differ in the coefficient of thermal expansion, so laying them close to each other is unacceptable. The interval between these types of bricks should be 0.6 cm.

It is recommended that the firebox and the rest of the stove, with the exception of the first three rows, be made of fireclay bricks. However, this material is highly expensive, so you need to make at least the inner part of the firebox from it.

When making a sauna stove with your own hands, pay special attention to the evenness of all surfaces. For cutting and joining bricks together, it is best to use a grinder. In relation to the order and drawings, the blanks are made in advance in the open air, since cutting bricks with a grinder is a rather complex process, during which dust is released.

In relation to the drawings, the corners must be rounded. This is necessary in order to improve the draft inside the stove. A fluff is installed at the mouth of the chimney, cutting through the wind it increases the draft.

Hand sauna stoves require metal elements. The reliability of the furnace is determined by the presence of a minimum number of steel elements in it. However, in order to reinforce the hanging masonry in the furnace, steel strips and angles are installed in it. Thus, it is possible to reduce the cost of the finished device.

After making a sauna stove with your own hands, the process of putting it into operation follows. Initially, under no circumstances should you heat a stove that has not yet dried out. Thus, its strength is reduced. The stove must be made during warm weather. It must dry for some time and only after that it begins to be put into use. The minimum amount of time for drying the oven is 15 days.

Next, warm drying is carried out for two weeks. To heat the stove, a minimum amount of coal and firewood is used, preferably from aspen. Firewood made from pine or birch is not suitable because when burned they release a large amount of heat and soot. There is paper in the cleaning door during drying; after it becomes dry, this process ends.

This is followed by the process of hot drying, in which the stove is heated several times a day, in the morning and in the evening. The load on her is gradually increasing. If there is a multi-pass oven, drying is carried out in winter.

Additionally, you can equip the stove with a stove bench. To make such a stove, you will need significantly more bricks. However, the bed can be used as a sleeping place or for drying a large number of wet things.

This stove is not equipped with an oven, since the heat from it immediately transfers to the stove bench.

The second option is an addition to the fireplace stove. There are two ways to organize such a stove. According to the first method, the fireplace is an addition to the back side of the stove and has a separate chimney from it. The second method of installing a fireplace involves heating it from the stove, thus, it is possible not only to save materials on the construction of the stove, but also to heat two rooms at once.

Another version of the Swedish stove is a small stove installed in dachas. It is used seasonally, periodically. Particularly relevant is the presence of a niche inside which clothes and shoes are dried. The amount of materials for the construction of such a stove is less, but the amount of heat generated as a result is also reduced.

DIY Swedish oven video:

A Swedish stove is a warm, cozy home and delicious food. Significant advantages of the stove: small area, less wood consumption, combination of a heating stove and cooking capabilities. We have prepared step-by-step instructions for you with drawings and order so that you can fold it yourself.

Foundation - monolithic concrete

Materials

Concrete grade B15 (M200) is suitable for the foundation for the furnace. To prepare such concrete, the components are taken in the following proportion: cement - 1 part, crushed stone - 4 parts, sand - 2 parts.

Cement must be taken at least M400. The coarse aggregate can be crushed stone or gravel, the particle size of which does not exceed 30 mm. Sand with impurities of no more than 10% is suitable for concrete work. These include clay, mica, organic origin and dust particles. Impurities in coarse aggregate should be less than 2%.

The required materials for the foundation can be calculated based on the consumption per 1 m 3 of ready-made concrete:

- Cement M400 - 325 kg/m3.

- Sand - 1300 kg/m3.

- Gravel (crushed stone) - 1300 kg/m3.

- Water - 205 l/m3.

Tools

To carry out concrete work, you must have a tool with which:

- lay the concrete mixture (shovel, trowel);

- compact (tampers, probe);

- smooth (ironing board, trowel, grout, iron, corner).

1 - dipstick; 2 — narrow tamper; 3 - round tamper; 4 — square tamper; 5 - ironing board; 6 - scraper; 7 - half-grater; 8 — ironing board

1 - dipstick; 2 — narrow tamper; 3 - round tamper; 4 — square tamper; 5 - ironing board; 6 - scraper; 7 - half-grater; 8 — ironing board

Sequence of concreting

It is very important to determine the depth to which you need to lay the foundation for the stove. This depends on the ability of the soil to resist loads on it (bearing capacity). There are quite a lot of soils with weak bearing capacity. Under the influence of loads, they can change their original structure (subsiding loess and containing soluble salts, swelling clay, of biological origin, as well as water-saturated, increasing in volume in winter).

So, for example, for fine (silty) sands, sandy loams, loams and clays, in which groundwater is located above the depth of soil freezing, the bottom of the foundation is assigned below this level. The depth of freezing is determined based on the results of long-term observations.

1 - sand cushion; 2 - gravel; 3 — freezing depth; 4 - monolithic foundation; 5 - waterproofing; 6 — floor level; 7 - brickwork

1 - sand cushion; 2 - gravel; 3 — freezing depth; 4 - monolithic foundation; 5 - waterproofing; 6 — floor level; 7 - brickwork

This is the case if the house may not be heated in winter. If the house is heated throughout the winter, then the base of the foundation should be at a depth of more than 50 cm from the layout of the land plot.

In dense soils with good bearing capacity, the foundation can be concreted without formwork. Then a hole is dug exactly according to the size of the foundation. If the soil crumbles, formwork is necessary. It is made from coniferous or deciduous wood, which is not subject to warping. The boards are taken with a thickness of at least 19 mm and a moisture content of no more than 25%.

At the bottom of the hole under the foundation, a cushion at least 15-20 cm thick is made of sand and gravel, which is compacted.

When laying the concrete mixture, be sure to tamp or compact it to release any air bubbles that appear in it. This increases the density of concrete, and therefore strength.

Caring for freshly laid concrete consists of maintaining the required temperature and humidity. This is protection from rapid drying of the concrete surface in windy, hot weather using some kind of wet covering (burlap, tarpaulin, wet sawdust or sand).

Protection of fresh concrete from excessive moisture, drying, and cooling is carried out for one to two weeks in accordance with the outside air temperature. The most important thing is that the concrete gains at least half of its full strength.

The formwork can be removed only when sufficient concrete strength (50%) has been achieved. Most often, this occurs no earlier than 7-14 days at temperatures from +5 to +20 °C. The higher the temperature, the faster the strength gains.

Waterproofing is placed on top of the hardened concrete (2 layers of roofing material). The size of the foundation must be taken 100 mm larger at each edge of the furnace.

Sequence of construction of a Swedish-type furnace

Materials

For stove masonry, you need a brick that will withstand high temperatures. These include ordinary clay bricks (GOST 390-96) and refractory fireclay bricks (GOST 530-2012).

Important! For kiln work, the use of silicate, hollow, unburnt, or cracked bricks is unacceptable.

In total, for a Swedish-type stove, excluding pipes, you need:

- Clay bricks - 505 pcs.

- Fireproof bricks - 25 pcs.

The furnace can be laid using clay-sand mortar, or a ready-made fire-resistant mortar for furnace work. Today, stores offer several types of such solutions.

A clay-sand solution can be prepared based on the following proportion for clay of different fat contents:

- Oily clay (2-4% sand) - 1 part clay: 2.5 parts sand.

- Medium clay (15% sand) - 1 part clay: 1.5 parts sand.

- Skinny clay (30% sand) - 1:1.

To prepare the solution, the clay is first soaked for 24 hours, then sand is gradually added to it in portions, constantly stirring until smooth. Water is also added in portions. Finally, you need to add water immediately before work. The clay solution should slide off the shovel easily, without spreading.

Furnace appliances

- Blower door (140x140 mm) - 1 pc.

- Fire door (210x250 mm) - 1 pc.

- Cleaning door - 5 pcs.

- Gate valve with hole (120x210 mm) - 1 pc.

- Oven (300x365x450 mm) - 1 pc.

- Plate (410x710 mm) - 1 pc.

- Grate – 1 pc.

- Metal sheet (750x500 mm) - 1 pc.

The oven can be made from sheet steel by welding. For protection, the outer surface is coated with fire-resistant enamels or varnishes.

Directly under the firebox a metal sheet (750x500 mm) is laid on asbestos cement.

Tools for laying a furnace

1 - pickaxe; 2 - various trowels; 3 - jointing; 4 - level; 5 - square; 6 — mallet; 7 - plumb line

1 - pickaxe; 2 - various trowels; 3 - jointing; 4 - level; 5 - square; 6 — mallet; 7 - plumb line

The firebox and smoke circulation (chimney) are the main parts of the stove body. Fuel is burned in the firebox. Smoke circulation increases the internal surface of the stove, accumulating heat in its mass, and transferring it to the heated room.

External view of the oven: 1 - cleaning doors; 2 — ash door; 3 - combustion door; 4 — oven; 5 - hob; 6 - valve

External view of the oven: 1 - cleaning doors; 2 — ash door; 3 - combustion door; 4 — oven; 5 - hob; 6 - valve

A grate is installed in the bottom of the firebox to provide air access to the fire. To ensure a normal combustion process, the draft in the furnace is regulated by a certain position of the combustion and ash doors. The heat output of the Shvedka stove in question is 3200 kcal/hour. It includes a cooking chamber and an oven.

It is necessary to begin furnace work only if there is a covering over the intended location of the furnace, at least temporarily. It is advisable to first make a selection of bricks for each row, combing them and tying them dry.

Orders

Before starting masonry, it is necessary to check all the dimensions of the foundation and determine the orientation of the furnace, including where the pipe will pass through the ceiling, as well as the roof. Immediately before work, ordinary clay bricks are soaked for 2 minutes, and fireclay bricks are only rinsed.

The first and second rows are laid with seams bandaged at least 1/2 brick. For masonry with ordinary clay bricks, a joint of less than 5 mm is required. It is allowed in the case of using 3/4 bricks to bandage 1/4 bricks.

Important! The masonry must be carried out while maintaining verticality along the plumb line and horizontality along the level of all seams.

The third and fourth rows form the ash chamber. There are also 3 cleaning doors installed here. They are inserted with a gap of 3-5 mm directly during masonry work. The gap is filled with asbestos cord. The top of the doors should be level with the horizontal joint of the masonry.

In the fifth row, the firebox is laid out with refractory bricks, the thickness of the seam for which should not be more than 3 mm. A grate is also installed here with a gap of 3-5 mm. The grate openings are directed along the firebox. The gap is filled with sand or ash. An oven is also installed in this row. The formation of chimneys begins at the rear of the furnace.

Important! It is not allowed to bind refractory and clay bricks, since they have different expansion rates under the influence of temperature and can contribute to the formation of cracks.

The sixth, seventh, eighth, ninth rows form the combustion chamber. The combustion chamber door is installed with a gap (3-5 mm) filled with asbestos cord. The wire screwed to the door is embedded in the brickwork. Fireclay bricks are placed on edge between the furnace and oven.

The tenth row involves covering the oven. The partition between the oven and the furnace is raised by 1-2 cm. Next, a layer of clay-sand mortar is laid on the oven to the level of the partition. A corner of 1000x40x40 mm is placed on the front side under the slab.

Eleventh row. The hob is laid and smoke channels are then formed.

Twelfth to sixteenth rows. The cooking chamber and chimney channels are formed, taking into account the ligation of the seams.

Seventeenth, eighteenth rows. To cover the cooking chamber, bricks are placed on strip steel and corners. A wire is screwed to them and embedded in the masonry.

Two cleaning doors are installed in the nineteenth and twentieth rows.

The twenty-first to twenty-eighth rows form chimneys according to the order. In the twenty-seventh row, a valve is also installed with a gap (3-5 mm) and sealed with an asbestos cord.

In the twenty-ninth row, the stove masonry is expanded by 5 cm for the cornice. All channels are blocked, except for the pipe.

The thirtieth row suggests an expansion of another 5 cm.

Thirty-first row. The furnace size is reduced to the original size.

Features of pipe laying

Next, a pipe the size of five bricks is laid. Three rows up to the ceiling, pipe fluffing begins to protect the wooden floor structures from hot gases. The thickness of the pipe in this place should be 1.5 bricks. They also increase the thickness of the pipe when passing through wooden roof structures. A metal cap is installed on top of the pipe. The entire outer part of the pipe is laid using cement-sand masonry mortar.

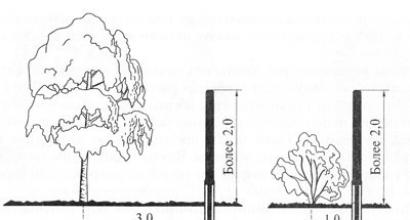

The height of the pipe above the roof is laid out according to the diagram. To increase traction, the height is related to the distance from the roof ridge.

The oven will fill your beloved home with warmth, comfort and kindness!

Every owner who has a house or cottage, with the onset of autumn and the prospect of winter, thinks about warm housing, and the Shvedka heating and cooking stove with his own hands is like a way out of this situation.

Due to the distance from the city heating network and the desire to purchase autonomous heating, like the desire of most residents of residential areas, they dream of their own autonomous heating supply, the thought comes about ways to heat their own homes.

Of all the types of autonomous (country-country) heating, the heating and cooking stove of the Shvedka type attracts your attention - a cooking stove with a stove.

It has the ability to heat several rooms at once and another big plus is that you can use it to cook! Photos and videos of such a stove can be easily found on the Internet.

Designs and modifications

The design of this furnace has excellent heat transfer properties of up to 3.5 kW (3000 kcal/h) with a firing frequency of only once every 24 hours and 4.1 kW (3500 kcal/h) with twice heating.

From an economic point of view, the stove heats a fairly large room due to a closed firebox, where the heat is retained in a direct chimney and the heating effect is transferred to the walls of the stove.

This is where all the efficiency of heat conservation lies, equal to 75% efficiency. To completely utilize heat, a heat exchanger is built into the furnace - a coil where the water is heated.

The dimensions of the stove are designed to heat the entire area of the house. But this does not mean that it will be able to heat a house of 150 square meters.

When determining the installation of a heating cooking stove, it is necessary to take into account that a small room is not suitable for this purpose, since there will not be enough air for the combustion process of the stove. To do this, you need a room of at least 16 square meters.

The Swedish heating cooking stove has various modifications and can satisfy the various whims of the owner, it all depends on what its price is.

In order to build a heating cooking stove as indicated above, you need to select the location of the stove itself and its type:

- wall - along a flat wall;

- corner - in the corner of the room;

- island - in the center of the room;

- built-in – built into the wall;

- suspended - suspended from the ceiling.

The attached stove can be placed anywhere:

- near a wall that is fireproof and in which communications do not pass;

- no electrical wiring;

- Gas supply pipes do not pass through and it is impossible;

- no water supply pipelines.

Often, they try to place attached models in the center of the wall, while connecting it to an existing chimney.

Its main part is located on (in):

- kitchen;

- dining room;

- dining room.

The second part (rear) goes into the next room:

- bedroom;

- living room;

- children's room

When constructing a stove, during the construction of a house, the chimney hog is built into a load-bearing wall, which is lined with non-combustible materials. The stove is installed in the corner of the room in cases where this is due to the interior design or the presence of a chimney.

Advice. Do not place the stove close to, to the side of or opposite windows and doors, that is, in the path of drafts, otherwise draft problems will arise.

The large-scale furnace must be installed on a foundation separate from the building structure. But issues related to fire safety are especially important.

The stove must be securely insulated from:

- partitions;

- gender;

- other building materials of highly flammable structures.

If the wall against which the stove is installed is made of materials that are easily subject to combustion, then it is necessary to build another half-brick partition, which should be wider in length than the firebox.

In front of the firebox doors, the construction instructions provide for a free space of at least one and a half meters, which also ensures fire safety of the area in front of the firebox.

For these purposes the following is used:

- stone slabs;

- ceramic tiles;

- metal sheets.

Operating principle of the furnace

Let's keep in mind that the outer wall is made of half a brick, and the base is an oven and a water-heating box.

A cast iron stove is used as a cooking surface, which increases heat transfer, and above it there will be a cooking chamber with a niche with steel doors.

Furnaces of this type are designed for both summer and winter use. In summer you can cook food and heat water on it.

The oven functions as follows:

- hot water from the firebox goes under the hob;

- The stove is heated, as well as the oven is heated;

- The flue gases are then removed through the chimney bur.

In the winter period of the year, the process is identical, but the flue gases, after heating the stove and cabinet, do not go into the chimney, but into the heating ducts and pass into the closed surface of the chamber, heat it, and only then are removed.

Material used in construction

A Swedish heating stove requires the following materials during its construction:

- 230-255 pieces of red brick (special for stoves);

- 250 kilograms of high-quality clay for mortar;

- 250 kilograms of fine sand;

- steel corner 45x45x3 mm;

- steel strips 40x3 mm;

- fire doors 270x300 mm;

- ash door;

- a hob made of cast iron with burners or thick steel;

- view latch;

- water heating box;

- drying box of any size.

Masonry and construction of the furnace

The foundation is made typical for all buildings.

- The first and second rows are laid from solid bricks. A zone chamber is formed between the third and fifth rows, doors are mounted on the ash pan, and a ceiling is installed on the fifth row.

- There is also space for a drying chamber., and the box is taken according to its dimensions.

- The Swedish long-burning heating and cooking stove is built inwards with your own hands, starting from the sixth row of bricks. This is done to install the grate, and then the firebox door.

- The eighth and ninth row is the future firebox, here you need to line the drying box.

- Then, in the eleventh row, steel strips are laid out on the surface of the box. Next, all this is covered with a solution of sand and clay.

At this stage, you need to remember to leave room for the future chimney. - Twelfth row. In it, bricks are laid directly on the mortar layer, and a place is also prepared for the further installation of the hob.

We also determine the sizes of the consumables that we have already prepared for our oven. - The slabs are laid on top of the thirteenth row, and a hot water tank is also installed, which partially heats the chimney.

- The fourteenth row provides for the installation of a chimney.

After meeting all the requirements, clear sequence and recommendations, your stove will function for a long time and will also warm you and your loved ones.

Advice. It is necessary to carry out furnace maintenance work correctly and on time.