How to select and connect a voltage stabilizer for a gas heating boiler. Which stabilizer to choose for a heating boiler? Stabilizer for heating boilers

Gas appliances are often equipped with electronic controls. Such heating boilers are connected to the network, and therefore are sensitive to the quality of the electrical supply. It has been proven that every fourth breakdown occurs due to network instability. Service centers refuse to repair equipment after such breakdowns. Therefore, you need to install a voltage stabilizer for a gas boiler.

How to choose the right device so that it protects the boiler to the maximum? We'll tell you in the article.

Do I need a stabilizer?

Many models of heating equipment “” (Baxi), “”, “” include electronic control and an automation unit. This includes the main module with the sensors controlled by it. The latter control the operation of the boiler components, ensuring safe operation.

Automation is sensitive to voltage quality. For its normal operation, a pure sine wave is required, as we wrote about in the article “”. That is, the current supply must be constant and stable. If the board burns out during the next surge, replacement will cost 30–50% of the total cost of the equipment.

Installing a stabilizer is simply necessary to protect the device. It adjusts the frequency of the current, so all systems function without overloads or breakdowns.

Some users still use old Soviet units with manual ignition and a complete lack of safety systems. They argue that adding additional protective devices is just a waste of money. One of the typical objections sounds like this: “In our area (house), network surges rarely happen. They are not so significant as to cause harm to the equipment.”

Let's look at the facts:

- No one is immune from natural phenomena: a storm, hurricane, strong wind, thunderstorm - all this can break the transmission line.

- The number of consumers connecting to the line is growing, which can make the supply unstable. And if the neighbors started renovations and turned on the angle grinder, then your network is guaranteed to receive a “jump.”

- The human factor plays a role: unscrupulous work of an electrician, damage to wiring during repairs - all accidents cannot be avoided.

Did you know? When connecting a boiler without a stabilizer, the company has the right to refuse warranty repairs.

What kind of protective device do you need? Let's start by getting to know their varieties.

Types of stabilizers

Let's look at the types based on their operating principle.

Relay or electronic. Connect to a network with a range of 135–315 V. One of the cheapest devices. The advantages of the relay type include:

- Good response speed (100 ms).

- Compact and light weight.

- Stable sinusoid. Output current accuracy is 7.5%.

- Quite noisy operation (clicks are heard).

- When switching windings, the light may flash.

- Short service life.

Electromechanical or servo-driven. The voltage is regulated by a brush that moves around the electric motor.

Advantages:

- High accuracy (3%).

- Work in a wide range.

- Smooth adjustment of output frequency.

- Low cost.

Flaws:

- After three to four years, the adjustment brush will have to be replaced.

- The device will not function in a cold room.

- Slow reaction.

- Due to the operating principle, it may openly spark.

Triac or thyristor. This is the best device today, although its cost is higher than the previous two. High operating accuracy of 2–3% due to the large number of windings. Run-up - 214–226 V.

- High speed (10–20 ms) and accuracy.

- Stable and quiet operation.

- High price.

Double conversion (inventory). A separate type of protection that can be called the most reliable. Initially, the device converts alternating current into direct current, and then again into alternating current with a pure sine wave. The operating range is 120–300 V. Instantly responds to a surge or drop in voltage.

One of the disadvantages is the high cost of the device.

Pulse width (PWM). The device is based on the operation of a pulse generator. It produces precise current output. Allows full synchronization with a gas boiler. Recommended for connection to a low-frequency network.

Which device is better to choose also depends on the number of phases. You can choose a device with a built-in battery that will maintain operation during a power outage.

Number of phases

The choice of the number of phases depends on the network parameters. If it is single-phase, then a protective device of the same type is needed.

Single phase. Suitable for wall-mounted and floor heating equipment. Often installed in houses and apartments with network values of 220 V. Serves to correct power up to 135 kVA.

Three-phase. It is used more for industrial purposes for connecting in boiler rooms. Power range 380–400 V. Can also be used in domestic conditions if the connection parameters correspond to the declared ones.

What to consider when choosing

To choose the best model, pay attention to the following parameters:

- Boiler power. Electric models of different brands “”, “”, “”, “” have different operating ranges - it can be 10 or 24 kW. This must be taken into account when choosing.

- Response time. Specified in milliseconds (ms). The parameter will tell you how long it will take for the stabilizer to equalize the voltage during a surge.

- Input voltage. Recommended range 140–260 W.

- Output correction accuracy. This way you will find out how well your boiler is “powered”.

- Working temperature. This refers to the ambient temperature at which the equipment operates normally. Usually it is +5 – +40 degrees.

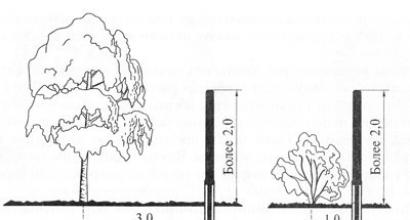

- Placement method. Wall-mounted options are lighter and more compact, taking up minimal space. Floor-standing ones are more often used for industrial purposes for high-power equipment.

How to connect a stabilizer

Before installation, read the instructions and technical documentation of the device.

- The device is located in a dry room at the temperature specified in the passport.

- The unit is placed away from flammable substances.

- The device must not be placed in closed cabinets or cabinets. It is important to ensure normal air circulation.

- The connection to the boiler is made through a grounded socket.

See diagram below:

Where to buy the device? This can be done in an online store or hardware stores.

Most often, the protective device breaks down during prolonged operation at low voltage (170 V). When connecting, observe the operating voltage at the input.

Why do you hear clicking noises when working?

This question is often asked by users on forums. There are several reasons for this:

- Clicks are heard when the power is selected incorrectly. When the energy values are outside the permissible limits, the stabilizer turns off. A click is heard. The solution is to choose a suitable device.

- Poor soldering of contacts. More often found in inexpensive versions. During use, a crack appears at the soldering point, which causes extraneous sounds.

- Mechanical type of equipment. Clicking sounds occur when switching modes.

Now you know what to look for when choosing, you have compared the advantages and disadvantages, and the connection principle. All that remains is to figure out the choice of model, its parameters and cost.

Rating of popular models

The review is based on consumer reviews.

"Resanta ASN-500 N/1-C"

Single-phase relay type stabilizer. The compact case fits well on the wall. Provides equipment protection during voltage surges in a 220/380 V network. The built-in filter eliminates interference, the current frequency is automatically adjusted. "Resanta" works in a wide range of temperatures, but does not tolerate high humidity in the room.

Price from 2,000 rubles.

Paul

I bought Resanta for a boiler with a circulation pump. I carried out a test, tried connecting a TV and a microwave to it - it’s suitable for any equipment. After connecting to the heating equipment, it has been working stably for a year, without shutdowns. There were no problems with the instructions, I connected everything myself. Now I don’t worry that the electronics will fail, because repairs are expensive. I recommend it to all my friends.

"Shpiel InStab IS3500"

Model of the InStab inverter converter from the Russian manufacturer Shtil. A single-phase device is perfect for protecting gas double-circuit boilers, refrigeration, and household appliances. Available in wall and floor versions. LCD display and LEDs help you keep track of the current mode.

- Instantly reacts to changes in the network.

- Does not distort the voltage in the primary network.

- Performs a double conversion.

- Built-in protection against short circuit (short circuit), overheating, overload.

- Forced cooling by fan.

- Noise filter installed.

Cost from 22,000 rubles.

Alexander

Initially I was looking for an inverter option. It is more reliable and produces a high-quality sine wave, unlike relays. While it is functioning normally, it is on the floor in a horizontal position. True, it makes noise during operation, which is annoying. Probably due to forced cooling by fans. It’s better to secure the equipment once than to call a technician and overpay later. So far I'm happy with the purchase, the main thing is that everything is protected.

"Bastion Teplocom ST-5552"

Wall-mounted single-phase relay type device. Protects electrical appliances, improving the quality of power supply.

Can be installed in the private sector, apartment, office, or enterprise. The case is simply mounted on the wall thanks to three-point brackets. LED backlight softly illuminates the panel at night.

Short circuit protection and automatic shutdown in case of emergency are provided.

Price from 3,000 rubles.

Victor

I have had a Buderus dual-circuit unit at home for a long time. It heated the water and the room perfectly until one day it broke down. It was autumn, winter was approaching, so the master was immediately called. After conducting diagnostics, he reported that the electronic board had failed. It turned out that the part was sensitive to network deviations. I recommended installing a stabilizer. I chose the budget option Teplocom St-555. He pleased me with clear instructions and a lightweight body. There are mounts for hanging, but mine is on the floor. The manufacturer provides a 5-year warranty!

The connection is easy: the plug is plugged into the network, and the socket is on the cable to the boiler. I've been using it for 2 years now and no problems with the equipment. “Teplocom” is constantly on, most often instability occurs at night. The only inconvenience is the short wires. But if you consider how much the device costs, this minus can be ignored.

Having realized all the advantages and disadvantages, as well as having become familiar with the types of protective devices, you can go shopping. Follow our recommendations, correlate the power of the heating unit with the parameters of the stabilizer. Consider the number of connected equipment. Good luck with your choice!

Modern gas boilers in their design contain a large number of elements, the operation of which depends on a reliable power supply. To ensure proper operation of all electrical and electronic components, special stabilizing devices are used. Before choosing a voltage stabilizer for a gas boiler, you need to find out what type of device is worth purchasing, and how the different types differ.

Most of the instructions for working with the most popular gas boilers do not contain any increased power requirements. As a rule, this equipment is powered from a standard household network, that is, for the operation of such equipment, the same voltage is required as for conventional household appliances.

The standard voltage varies between 198 - 242V or 207 - 253 V.

But if you look in more detail, the standards do not always correspond to real conditions. It is impossible to really force the electricity supplier to bring the network to the required parameters that are specified in the operating instructions.

It turns out that if you do not take into account the installation of this device, then too high or too low voltage can lead to failure of expensive structural elements.

In order to understand the need for such a device as a voltage stabilizer for gas boilers, you need to take a closer look at its functioning in working conditions. Household gas boilers are designed to operate when powered from a household network of 220-230V with an error of ±10-15%. During a voltage drop of 20V, the equipment will nevertheless continue to operate normally.

But if it drops to 140-180V, which is not a rare case in the private sector, where weak power lines are obviously installed. In this case, the operation of the device will be unstable, some functions of the device may be disabled, or it may be completely turned off until normal power supply is restored.

In some more serious situations, instead of a voltage drop, voltage surges occur. The voltage in such situations can briefly rise to a level of 250-300V, which can damage the software board, cause electronic burnouts, or complete failure of printed circuit boards. After this, either expensive repairs or complete replacement of equipment may be required.

The voltage may drop or “jump” due to the following factors:

- increase in load on the line due to an increase in the number of consuming devices;

- unauthorized intervention into the switchboard in the entrance or a box on the street by a person who does not have the appropriate qualifications, which causes a short circuit;

- throwing wires of live lines over each other in case of weather conditions (strong wind, icing of wires).

If we take into account all these factors, then it is necessary to acquire a current stabilizer for a gas boiler, which will prevent its premature failure. But what types of stabilizers are there and how to choose the one you need?

It turns out that purchasing a stabilizer is not a mandatory requirement. But in some cases it is necessary. Therefore, whether it is worth purchasing this equipment should only be decided by the user himself. And our task is to give you information about which voltage stabilizer is the best.

Design and principle of operation

The whole point of this type of device is to dampen voltage surges and bring it to the set values.

All voltage stabilizers are designed to perform two tasks: in the event of a voltage drop or surge, bring it to the maximum possible value of 220V, or break the circuit if the required value is exceeded, if the stabilizer is not able to normalize it. This ensures the correct operation of heating appliances and protects sensitive electronics from overload.

Fundamentally, all types of voltage stabilizers are similar in internal structure. As a rule, the following elements are enclosed inside the case:

- An autotransformer with several windings, whose task is to output voltage with established characteristics.

- A monitoring device whose task is to detect changes in input voltage.

- Fuses are used to cut off the power supply if the parameters exceed the operating range tolerances.

- Control automation is used to change the path of current through the windings of the transformer when there is a difference between the input and output voltages.

As an additional parameter, the stabilizer may have rechargeable batteries that allow you to provide power to connected devices when the voltage in the network disappears.

The essence of the operation of a voltage stabilizer is not particularly complicated. If the input voltage deviates from the set value, the automation changes the direction of current flow through the transformer windings so that the output has a constant voltage of 220V. Technically, voltage stabilization can be achieved by different methods, it all depends on the type of device.

Types of stabilizers

Stabilizers that are commercially available are classified according to their operating principle, which should be taken into account before choosing the right product. Modern stabilizing devices come in four types:

- electromechanical (with moving contact). The essence of the work is to move the current-collecting brush along the contacts of the boost transformer using a servo drive. This type of stabilizer design can allow voltage adjustment over a wide range of values. But such devices can only be used in warm rooms. In addition, this stabilizer requires periodic replacement of the brushes on the electromechanical regulator, and it is also extremely sensitive to dust;

- relay (relays are used as power switches). These models use a relay to switch between transformer windings. Because of this, the design has no moving parts, which increases its reliability. But because of this, the parameters of this device largely depend on the number of stages of the autotransformer. For this reason, before purchasing such a device, you need to make sure that the declared sensitivity and range of adjustments are required by the boiler manufacturer;

- electronic or triac (in these devices, relays are replaced by thyristors). Semiconductor devices called thyristors are responsible for adjusting the current parameters in these devices. Thanks to this, the devices have a very high response speed. Thyristor devices are trouble-free devices, they have a silent operation mode, and they are not demanding in terms of operating conditions. The disadvantages of such devices include the rather high cost;

- inverter (double conversion). Their distinctive feature is the absence of an oversized transformer. The current supplied to them from the network is rectified and adjusted to the required readings, and then, using an inverter, it is converted back into alternating current. Using a capacitor, additional energy is stored, which significantly improves the performance of the device.

In addition, there are stabilizers with pulse-width modulation (PWM), which involve voltage correction using a pulse generator, as well as ferroresonant stabilizers, which operate on the principle of saturating magnetic transformer cores. However, these are outdated types of stabilizing devices that are practically not used in everyday life.

Stabilizers also differ in voltage type and number of phases. Household electricity supplies have the following uses:

- single-phase lines with a voltage of 220V;

- three-phase lines with a voltage of 380V.

The latter type is in most cases the most preferable, since the consumer has at his disposal three single-phase lines with a voltage of 220V. This voltage can be obtained if one of the phases is connected to the neutral wire. Based on the number of existing phases, the choice of the type of the best stabilizer will depend.

But you need to remember that a good gas boiler is essentially a low-power consumer. Therefore, connecting it to a three-phase power supply network does not make sense. Stable operation of the unit is freely ensured by a single-phase line with a single-phase device.

Advantages and disadvantages

The advantage of uninterruptible power supply, which is inherent in a UPS, may not be of primary importance for the following reasons:

- voltage surges in networks occur much more often than accidents that lead to a complete shutdown of the power supply;

- even in the event of a complete power outage, it does not lead to sudden cooling of the premises and further defrosting of the heating system, since the house (or other building where the heating boiler is located) in this case plays the role of a heat accumulator and can maintain the optimal temperature for a long time.

Based on everything that was said earlier, the conclusion is that if:

- the amplitude of voltage surges does not exceed the maximum operating range of the stabilizer;

- Long-term power outages occur extremely rarely or are absent altogether, therefore, connecting a heating boiler through a voltage-stabilizing device is the most convenient and economically feasible than purchasing a UPS.

There are also disadvantages to powering a gas boiler through a 220V voltage stabilizer.

Connecting heating gas equipment through a stabilizer cannot completely eliminate all problems. For example, here’s what no stabilizer can handle:

- the stabilizer is not able to protect the equipment if the overhead power line supplying electricity to the house is struck by lightning, in this situation it is necessary to install a surge protection device (SPD);

- the stabilizer is not capable of changing anything if the electricity goes out altogether; for such situations an uninterruptible power supply (UPS) is required;

- only one type of stabilizer, inverter, can correct the frequency of the input voltage; the others are useless in this situation. As an alternative, you need to install an online UPS.

And now some pretty useful information. Cheaper devices can easily cope with every task that stabilizers must solve:

- to protect the gas boiler from interference in the supply circuit, a regular mains filter or a filter included in the UPS can be easily dealt with;

- The loss of power to the boiler at very low or, conversely, very high voltage can be prevented using a much cheaper device - a power control relay.

It is clear that connecting the boiler through a voltage stabilizer is not the most rational solution. Even the most mediocre online UPS will be one level better at solving the problem than the best voltage stabilizer for a gas boiler. And if you additionally install a voltage relay and a surge protector to the UPS, you can provide the boiler with almost impenetrable protection.

What to look for when choosing?

The choice of a voltage stabilizer for a gas boiler depends on several main criteria:

- Number of phases. Everything is simple here. All gas boilers with electronic control require zero and one of the phases to operate. Based on this, only single-phase stabilizers should be the subject of interest. And their price is much lower compared to three-phase ones.

- Voltage stabilization speed. There are no devices that can instantly adjust the output current when the input current surges. There is always a certain pause that is needed for the protective electronics to operate. And during this period of time, voltage with unacceptable parameters will be supplied to the boiler, which causes the possibility of failure of the boiler. Servo stabilizers have the longest response period. They can regulate voltage at a speed of 10-40V/sec. This suggests that in practice, voltage equalization will take 0.1-0.2 seconds. And this is extremely undesirable for some boiler models, since there is a high risk of their failure. Thyristor stabilizers have the highest response speed; they can level the values to optimal characteristics in 10-20 ms.

- Power. It is necessary to determine how powerful the device should be. Naturally, you don’t have to worry about this problem and just buy a device with a large supply of power, but not everyone can afford it. If a boiler has already been selected, then everything is extremely simple. You just need to open the instruction manual and find out the power consumption. For example, Baksi Luna-3, depending on how sophisticated it is, consumes from 80 to 165 W. You just need to take this value and multiply it by 1.3 - the resulting value will be the minimum power of the stabilizer.

Do not confuse the consumed electrical power with the produced thermal power of the boiler!

In the case when the boiler has not yet been purchased, but the stabilizer needs to be purchased right now, you need to look for a model from 400W. This will be enough, since for the most part the power of boilers varies from 70 to 250 W. There are models whose power consumption is within 500W, but such a device can hardly be purchased by chance.

It must be remembered that some manufacturers of stabilizers indicate power in Volt-Amps, and not in Watts. They do this on purpose in order to mislead buyers. The total power is always much higher due to the fact that it includes a reactive component. Because of this, the illusion is created that the stabilizer is steeper than it actually is.

If, nevertheless, it was possible to find out only the total power of the stabilizing device (VA), it must be multiplied by a correction factor of 0.7, the resulting value will be the active power in Watts.

- Type. We choose between four existing varieties. It is better to immediately exclude electromechanical ones, as they pose a danger.

Electromechanical (later) stabilizing devices are strictly prohibited from being installed in the same room as gas equipment!

If there is a gas leak, sparks that appear when the moving contact moves along the windings of the autotransformer can cause an explosion. For working in a gas-filled room, the best option would be to use a triac (thyristor) stabilizer for a gas boiler.

Modern relay stabilizers are almost as good as electronic ones in terms of response speed. The only thing I would like to note about such devices is the relay clicks from time to time. If this factor is unacceptable, then it is better to select a thyristor/triac device; it is characterized by silent operation.

- Automatic restart. The presence of a restart feature greatly simplifies the operation of the boiler. If there is an excessive deviation of the input voltage and an overload occurs, an emergency shutdown of the device occurs. If automatic restart is possible, there is no need to manually start the gas boiler inverter. This function is quite useful in the case when strong voltage drops in the network are constant. In addition, thanks to this function, you can restore the operation of the equipment in the absence of owners.

To make choosing a stabilizer easier, we will discuss the key features of some of the most common models.

Rating of the best stabilizing devices

We bring to your attention our own TOP 7 best 220V stabilizers, which we compiled after studying numerous ratings of electrical appliance stores and customer reviews. These models are sorted in descending order of quality.

- Powerman AVS 1000D. Toroidal unit with high quality standards: low noise level, high efficiency, small dimensions and weight. The power of this model is 700 W, the operating temperature is in the range of 0...40°C, and the input voltage ranges from 140...260V. It has six adjustment stages and two outputs, and a response time of only 7 ms.

- Energy Ultra. One of the best electronic models for gas boilers Buderus, Baxi, Viessman. It has high technical parameters: load power 5000-20,000W, range 60V-265V, temporary overload up to 180%, accuracy within 3%, frost resistance from -30 to +40 °C, wall mounting type, absolute silent operation.

- Rucelf Boiler-600. An excellent device in a high-quality metal case, inside of which there is a well-insulated autotransformer. It has high technical parameters: power 600W, range 150V-250V, operation within 0...45°C, four stages of adjustment, and response time is 20 ms. There is one Euro socket, which is located below. Wall mounting type.

- Resanta ACH-500/1-C. A relay-type device with a power of 500 W and an input voltage of 160...240 V. Resanta brand products have two variations. The response time is 7 ms, has four stages of adjustment and built-in protection against overheating, short circuit, and high voltage. Connects to a grounded outlet.

- Sven AVR Slim-500. Despite its Chinese origin, the relay device has decent installation quality and technical characteristics: power 400W, four stages of adjustment, input voltage within 140...260 V. Sven is able to operate at temperatures from 0 to 40°C. Equipped with a toroidal autotransformer with an overheating sensor. Reaction time is only 10 ms.

- Calm R600ST. The only electronic stabilizer designed specifically for gas stakes. Thanks to triac switches, the operating voltage ranges from 150 to 275V. Device power – 480W, temperature range – 1…40°C, four-stage adjustment, response time is 40 ms. There is a separate circuit for each of the two Euro sockets. Completely silent operation.

- Bastion Teplocom ST-555. Another relay type model, but the power of which is an order of magnitude lower - 280 W, and the input voltage is 145...260 V. Also, unlike the Resanta brand, the Bastion response time is 20 ms, and the number of stages is only three. In addition, the device heats up during operation and does not have an automatic fuse.

The cost of stabilizing devices for gas heaters starts from 1,660 rubles, and the upper limit is about 50,000 rubles.

How to connect the device to the boiler?

Now you need to study the diagram of the correct connection of the stabilizing device.

First of all, in order to protect your gas boiler, you need a surge filter directly in front of it, and immediately after the incoming automation, a voltage control relay.

As a rule, in places where heating boilers are used, power is transmitted using a two-wire overhead line which is equipped with a TT grounding system. In such a situation, it is necessary to add an RCD with a setting current of up to 30 mA.

This gives the following diagram:

Attention! Both the stabilizer and the gas boiler must be equipped with grounding!

In order to ground the boiler (as well as other electrical appliances), the TT system requires a separate grounding circuit, which is completely isolated from the neutral working conductor, as well as from the rest of the network. The resistance of the grounding loop is calculated in accordance with the standards of the Electrical Installation Rules.

Conclusion: which stabilizer for a gas boiler to choose

From everything described above, we can summarize which stabilizing device is best suited for a gas boiler:

- single-phase;

- with a power of 400 W or 30-40% more boiler power;

- any type, except electromechanical, or install the electromechanical device in another room.

For consumers, the main criterion for choosing voltage stabilizers is the price of the product. For the same price, you can buy a device that is not suitable for gas equipment at all, or you can purchase a reliable model that will provide decent protection. Therefore, when choosing a stabilizing device, it is necessary to take into account the listed parameters, and not just the price.

Most modern heating boilers have an electronic control system that monitors compliance with the specified parameters and ensures safety during operation. All household heating boilers, with rare exceptions, are designed to be powered from a standard 230V 50Hz power supply. Unstable operation of the power supply network and voltage surges can pose a danger to the electronic “stuffing” of the device. To ensure reliable, long-term operation of the boiler and protect it from possible problems with the power supply, a voltage stabilizer is installed. In this article we will look at the issue of choosing the right stabilizer for your heating unit.

You can often hear the opinion that the presence of a voltage stabilizer is not so important. “My boiler has been working great without a stabilizer for ten years,” “it tolerates all changes normally,” say some owners, implying that buying this device is a waste of money.

Indeed, modern devices cope with small voltage fluctuations. Moreover, according to the interstate standard GOST 29322-2014, the mains voltage is not a constant value and should be 230 V plus or minus 10%. Accordingly, the standard voltage falls within the range of 207-253 V.

However, in real life, not everything always happens according to standards and sudden changes in parameters in the power supply network are not yet a fantasy. In addition, many different factors can cause possible problems, from weather conditions to human intervention. Therefore, installing a stabilizer still seems to be a justified decision and its purchase, in most cases, is less expensive than repairing a heating boiler in the event of an accident. In addition, many sellers define the established CH as a necessary condition for the warranty to be valid.

What types of stabilizers are suitable for boilers

Manufacturers produce many stabilizers of various models. The devices on the market can be divided into four types:

- electromechanical (servo-drive)

- relay

- electronic (thyristor)

- inverter

Each type has its own characteristics, pros and cons, which must be taken into account when selecting. Here is a brief overview of the equipment for each type.

Electromechanical

The principle of operation is based on the circular windings of a transformer, along which carbon brushes, controlled by a servo drive, move.

Pros: low cost, wide range of input voltage, accuracy and smoothness of regulation, ability to withstand overloads, ability to work at low temperatures and high humidity, reliable system of protection against overvoltage and overheating, long service life.

Minuses: low speed of adjustment (response), increased noise level, increased weight and dimensions compared to other types of devices.

Important! It is strictly forbidden to install electromechanical stabilizers in rooms with gas equipment! This limitation is due to the fact that during operation of a MV of this type, the formation of sparks is possible. If gas leaks, it may cause an explosion.

Such stabilizers can be installed for heating boilers, but it is not recommended to use them if there are frequent noticeable voltage surges. Also, due to safety requirements, a separate installation location is required.

Relay

A widely used modern type of stabilizer. Here, the current passed through the transformer winding is regulated by special relays, and not mechanically. Some resources provide information that relay MVs are not suitable for heating boilers due to their low performance. Indeed, the response speed of previously produced stabilizers of this type was low, but modern models do not have this drawback.

Pros: affordable cost, wide range and high speed of regulation, reliable protection system, compact size and light weight.

Minuses: step regulation, lack of power reserve, average noise level, short service life.

In terms of price/quality ratio, relay stabilizers are the best choice and are widely used with heating boilers.

Electronic

Electronic stabilizers regulate the current by also passing current through a transformer using electronic switches, which allows for the compact size of the device and its high efficiency.

Pros: wide range and high control speed, low noise level, compact size, long service life.

Minuses: high cost, step regulation, lack of power reserve.

Electronic stabilizers are a more advanced and universal solution for heating boilers. They have a higher cost than relay ones, therefore they are less common.

Inverter

In inverter stabilizers there is no transformer, here the alternating input current is first converted into direct current and then the required alternating voltage is generated from it.

Pros: wide range of input voltage and high accuracy of output voltage, high speed and smooth regulation, absence of noise, minimal size and weight, long service life.

Minuses: high cost, lack of power reserve.

Stabilizers of this type provide the highest quality regulation, but have the highest price among the listed types.

More information about the different types of voltage stabilizers for the home is written in the following article: what types and types of voltage stabilizers for the home exist?

What characteristics of a stabilizer should you consider when purchasing?

When selecting a voltage stabilizer, it is necessary to evaluate its key characteristics and their impact on the operation of the heating boiler. This will help you choose the model most suitable for specific operating conditions.

Stabilizer power

One of the main parameters for choosing a stabilizer for a heating boiler is power. You can find out how much power the boiler consumes in its passport. It is important not to get confused; for boilers, two values are usually indicated: the thermal power of the boiler (usually >10 kW) and the required electrical power consumption (average 100-200 W or 0.1-0.2 kW).

When starting the boiler, the value may increase for a short time; the found parameter must be taken with a reserve. We must also not forget about the accompanying equipment that may serve the stabilizer together with the boiler; this could be, for example, a circulation pump, if it is not built into the boiler itself.

In addition, if the input current drops, then the ability of the stabilizer to increase it also drops; it is also necessary to take into account the voltage drop. For example, if the outlet has 170 V instead of the required 230 V, the efficiency of the stabilizer will drop to 80% of the rated power, i.e. A 500 W stabilizer should be calculated as for 400 W.

Thus, to calculate the required power of the stabilizer with a reserve for starting current and sag at low voltage, we need to multiply the total power of the boiler and related equipment (if any) by a factor of 1.5. If the voltage in the network is very low, it would not be a bad idea to increase the coefficient to 1.7.

Example: Boiler power is 150 W, circulation pump 100 W. We multiply their total power (250 W) by a factor of 1.7. We get a minimum stabilizer power of 425 W.

How much does the input voltage drop?

The stabilizer brings the voltage from the network to the required 230 V. Depending on the magnitude of the voltage drop in the network, stabilizers are produced with different input voltage ranges. To find out what parameters we need a device with, we need to take measurements.

For this you will need a voltmeter (multimeter). It is advisable to take measurements at different times of the day to see how the indicators change depending on the load on the network, while capturing the hours of maximum and minimum consumption (morning-afternoon-evening). It is better to write down the received data so as not to forget. It is advisable to take measurements within a few days. When finished, you can add 10-15 V in each direction to the peak values, this will provide a small margin.

If you get values of 180-240 V, then it is with this range that you need a stabilizer. In the private sector, outside the city, there may be more significant differences in the network, for example, from 140 to 270 V, which must be taken into account when purchasing.

The output voltage of the stabilizer is usually standard 230 V + -10%. To avoid problems due to lack of power, it is better to choose a stabilizer with an output voltage accuracy of no more than +-5%. This will ensure the parameters specified by the manufacturer and will be the key to long, uninterrupted operation.

Voltage stabilization speed

This parameter consists of two characteristics:

- regulation speed - measured in volts per second (V/s), shows the ability of the stabilizer to restore the standard output voltage in the event of significant deviations in the input;

- response time - indicated in milliseconds, shows the response time of the device to a change in voltage.

The higher the speed and the shorter the response time, the better the stabilizer protects your equipment. Good models have a regulation speed of 100 V/s or higher. This indicator allows the stabilizer to restore the required voltage almost instantly. A speed of 15-20 V/s is considered not a very good value, which can lead to short-term incorrect operation of particularly voltage-sensitive boilers.

An excellent response time is considered to be 5 ms or less. 10ms will be quite acceptable, and 20ms will be satisfactory. Large values already imply some risk.

Important! Inverter stabilizers use double conversion, as mentioned above, so they do not have a response time parameter.

Availability of protection and restart function

Almost all modern models of stabilizers have a protection system that turns off the device if it is unable to ensure normal operation in the event of a significant deviation in network parameters or, for example, overheats.

The voltage stabilizer for the boiler must have a restart function. What does this mean? When strong surges or a significant drop in voltage occur, the device turns off the output power, which results in the boiler shutting down. The stabilizer monitors the network parameters and when they return to an acceptable range, the power is restored, the boiler starts and continues to operate as normal.

If there is no restart function, then a manual restart is required to re-apply power. If the owners of the house are absent or away, this can cause inconvenience in winter and even lead to serious problems (defrosting and failure of the heating system and boiler). In very cheap models there may not be a restart function, which is a big minus. Pay attention to this when purchasing a stabilizer.

Design

Existing devices can vary greatly in weight and size, depending on their type. Wall and floor models are available, as well as options with a digital display and dial sensors. When choosing a stabilizer, do not forget to plan its installation location in advance, imagine how it will look in your interior, whether you want to hide it or, conversely, place it in a visible place near the boiler. Do not make the common mistake of placing the stabilizer directly under the boiler; this is prohibited due to safety requirements; if there is a leak, water from the boiler can flood the electrical appliance.

Popular brands and brands of voltage stabilizers

The market offers a wide variety of brands and models, produced by both Western manufacturers and domestic companies that have established production long ago and often offer good options in terms of price/quality ratio. Popular brands on the market are Luxeon, Logic Power, Resanta, Energy, Progress, Ruself, Lider, Sven.

Examples of reliable models of boiler stabilizers

Examples of good and reliable models of stabilizers for heating boilers by type.

Servo:

- Resanta ACH1000/1-EM;

- Luxeon LDS1500 Servo;

- RUCELF SDW-1000;

- Energy CHBT-1000/1;

- Elitech ACH 1500E.

Relay:

- LogicPower LPT-1000RV;

- Luxeon LDR-1000;

- Powercom TCA-1200;

- SVEN Neo R1000;

- BASTION Teplocom ST1300.

Electronic:

- Calm R 1200SPT;

- Luxeon EDR-2000;

- Progress 1000T;

- Lider PS 1200W-30;

- Awattom SNOPT-1.0.

An indispensable condition for the correct operation of European gas boilers of the brands “Ariston”, “Baksi”, “Beretta”, “Buderus”, “Visman” is maintaining a stable voltage within 210-230V, which will require the purchase of a stabilizer.

A service center that services heating equipment under warranty usually refuses free repairs if this condition is not met. Therefore, it is important to understand how to choose a voltage stabilizer for a gas boiler.

Do I need a voltage stabilizer for a gas boiler?

Modern heating boilers are equipped with sensitive automation, which is the “heart” of the boiler. The control unit regulates the operation of the burner, the intensity of coolant circulation, changes the operating mode if necessary, reading the room temperature, and also performs other functions. Automation is sensitive to voltage changes. With the next “jump” of voltage in the network, the control unit board may simply burn out. After this, the entire control unit will need to be replaced. Repairs, depending on the model, will cost 30-50% of the cost of the boiler.

Automation is sensitive to voltage changes. With the next “jump” of voltage in the network, the control unit board may simply burn out. After this, the entire control unit will need to be replaced. Repairs, depending on the model, will cost 30-50% of the cost of the boiler.

Manufacturers of volatile heating equipment recommend connecting the boiler to the electrical network through a stabilizer. Without connecting the electrical stabilizer, the company selling heating equipment has the right to refuse warranty service. For this reason, it is not recommended to turn on a gas boiler without a voltage stabilizer, even to check the functionality of the heating system.

Types of stabilizers for gas boilers

The consumer is offered a wide range of stabilizers that use different operating principles and ensure the safety of boiler automation with varying degrees of efficiency. When choosing the right equipment, you will need to consider several important aspects:- Price.

- Performance.

- Duration of operation.

- Input and output voltage range.

- Principle of operation.

Triac (thyristor) stabilizers

Today, triac stabilizers are considered better than other analogues, thanks to the following technical characteristics:- Performance is no more than 10-20 ms, depending on the model.

- Output voltage accuracy is 1-2.5%.

- Input voltage range from 120 to 280 V.

- Input output voltage control accuracy with a maximum error of 0.5%.

- Absolutely silent operation.

- Long service life.

The only drawback of the models is the relatively high cost compared to analogues. If desired, you can choose a thyristor stabilizer with an optimal price-quality ratio.

One of the main functions of a step stabilizer is to maintain the operation of the device when one of the triacs fails. In the event of an inter-winding short circuit, the boiler automation will remain operational.

A triac converter is suitable for networks with constant voltage surges and surges.

Relay (electronic) stabilizers

The relay (electronic) stabilizer is cheaper than the previous model. Its use is limited to connection to electrical networks with minor intermittent changes. Relay devices have the following characteristics:- Speed 100 ms.

- Output voltage accuracy 7.5%.

- Range 135-315 V.

The disadvantage of relay models is their relatively short service life and low quality. To increase the service life, hybrid stations using protective resistors have recently begun to be produced.

Servo-driven (electromechanical) stabilizers

Electromechanical (servo-drive) stabilizers operate using a special slider that moves the brushes along the contour using an electric motor. Thanks to this, the turns of the secondary winding are switched alternately.The advantages of this type of converters are:

- High precision and smooth adjustment of output voltage.

- Ability to withstand long-term extreme loads and maintain stable operation under overloads.

- Low cost stabilizer.

Double conversion stabilizers

The inverter stabilizer is almost ideal. There are no disadvantages (besides the high cost). The inverter stabilizing device responds very accurately and quickly to abrupt phenomena in the network. Provides smooth adjustment of the output voltage. The operating principle is based on the use of double conversion. Alternating current is transformed into direct current. After this, the conversion occurs back to alternating current, but at a stable frequency. The output produces a voltage with a stable sinusoid, which has a beneficial effect on the automation and boiler processor.

The operating principle is based on the use of double conversion. Alternating current is transformed into direct current. After this, the conversion occurs back to alternating current, but at a stable frequency. The output produces a voltage with a stable sinusoid, which has a beneficial effect on the automation and boiler processor.

When selecting a suitable model, it is necessary to take into account the following features of the double conversion stabilizer:

- No electromechanical interference.

- Durability.

- Operating input voltage range 120-300 V.

- Speed – the device reacts without delay to any surge or drop in voltage and equalizes it.

- Expensive – the cost of the device is from 15 to 60 thousand rubles. Some owners of gas boilers decide that it would be more advisable to purchase a UPS than to buy a stabilizer.

- Low efficiency - only 90%, which is quite low compared to other models.

Stabilizers with PWM

The operating principle of a stabilizer with pulse-width modulation is based on the use of a special pulse generator. The parameters of the voltage waves are constantly changing, depending on the difference between the input and output voltage. As a result, the stability of the output current frequency is ensured.The main advantage of a PWM station is the ability to fully synchronize with electricity-consuming equipment. A PWM voltage stabilizer used for gas boilers performs protective functions and also creates conditions for maximum processor performance. This type of converter is most in demand when the boiler is connected to a low-voltage electrical network.

Ferroresonant stabilizers

Ferroresonant modules use the principle of saturation of magnetic transformer cores. In the early 60s of the last century, devices were installed to stabilize the operation of household appliances.A ferroresonant voltage stabilizer for working with a gas boiler for domestic purposes is practically not used. The stations are installed in high-power boiler houses.

The advantages of converters include:

- High accuracy of output voltage, error no more than 1-3%.

- Speed of response.

How many phases should a stabilizer have?

The choice of a single- or three-phase voltage stabilizer for a gas boiler primarily depends on the parameters of the electrical wiring connected to the residential building. If the network supply is single-phase, an appropriate converter will be required.With a three-phase power supply, you will need to install either one stabilizer designed to connect three phases, or three single-phase ones, which will provide a more stable output voltage.

Single-phase stabilizers

Single-phase stabilizers are mainly used for domestic purposes. Installed in apartments and private houses. Connection to an electrical network with a rated voltage of 220 V is allowed. Household appliances are designed to rectify the full maximum power up to 135 kVA.Single-phase converters can also be used for industrial purposes. In this case, a three-phase network will require the simultaneous connection of three rectifiers. This decision may be justified if we consider that single-phase devices produce current with a more stable frequency and sinusoid.

Three-phase stabilizers

Three-phase stabilizers are mainly used for industrial purposes. It is allowed to connect the rectifier to boilers with high production capacity. Operating conditions recommend the use of three-phase modules for electrical networks with a rated power of 380 and 400 V.You can also connect a three-phase device for domestic purposes, provided that a network with a voltage of 380V is connected to a private house. But in general, for a low-power gas boiler, there is no need to install a three-phase model.

What stabilizer is needed for a gas boiler

For a gas boiler, a voltage stabilizer is better that meets several basic criteria:- Response time - this parameter is indicated in the technical documentation and is measured in ms (milliseconds). The lower the coefficient, the better it is for boiler automation. In essence, the response time means how long it takes for the stabilizer to adjust the voltage during the next surge.

- Input voltage range is a parameter indicating the boundaries within which the rectifier can operate. Upon reaching the limit values, the device will simply turn off the gas boiler. Frequent shutdowns during heating periods can lead to freezing of pipes. Therefore, the best voltage stabilizer for a gas boiler should have a spread of approximately 140-260 V.

- Correction levels - the accuracy of maintaining and stability of the output voltage depends on this coefficient. The more correction levels a device has, the better it copes with the assigned tasks.

- Operating temperature range – the requirement for the stabilizer is to maintain operability at ambient temperatures from +5 to +40°C. For industrial devices, a special casing is provided, which makes operation possible even at subzero temperatures.

Another important criterion is the type of installation. For gas boilers, mounted models that are light in weight are mainly used. Floor-standing (shelf) devices are designed for high-power three-phase boilers. The optimal solution would be to purchase a module with universal fasteners.

If we take into account all the above requirements, it becomes obvious that a gas boiler requires an electronic or relay, or, as an option, an inverter type of stabilizer. Only such models can fully cope with the load and power surges in the network, as well as ensure the functionality of the automation.

How to calculate the power of a voltage stabilizer

The required minimum power of a 220V stabilizer is calculated as follows:- It is necessary to find out the electrical power of the boiler automation and circulation pump. The coefficient is given in the technical documentation.

- Obtain the total power of all power consumption points connected to the station.

- Multiply the resulting amount by 1.3 - this will allow you to take into account the starting current. When the circulation pump is turned on, the actual electricity consumption can triple.

How to properly connect a stabilizer to a gas boiler

There are rules for installing a stabilizer, the implementation of which is necessary to ensure long-term and safe operation of the device. Detailed requirements are described in the technical documentation.The basic rules are as follows:

- The voltage stabilizer must be located in a dry place. It is strictly prohibited to install the device in rooms with high dampness: garages, bathrooms, etc.

- The module must not be placed in close proximity to flammable or flammable substances.

- Free access of fresh air to the device body is required. For this reason, installing the module in a cabinet is prohibited.

In order for gas heating boilers to work properly and as efficiently as possible, they are equipped with various automatic monitoring and control systems. Such equipment simplifies the operation of the coolant heater and makes this process safer. However, without a voltage stabilizer for a gas boiler, all these sensors, as well as the circulation pump and burner, are unlikely to work properly. Failures in the electrical network inevitably lead to problems in the boiler room.

What is it and why is it needed for a gas boiler?

Almost all gas boilers, regardless of the output power, require power supply. There are non-volatile models, but they cannot please you with particularly high efficiency. Most often, the heating of a private home is now formed around energy-dependent heating equipment with increased efficiency. And these are a variety of air blowing fans, electric burners, soft ignition devices, sensors, pumps and valves.

Buyers usually strive to choose a gas boiler with low fuel consumption, but maximum productivity. And such a unit necessarily requires electrical power. Moreover, the input voltage must be strictly sinusoidal and with minimal deviations from 220 V. Stabilizers are used for this. If there are problems in the network, they level the incoming electric current to the required parameters so that the heating boiler continues to operate uninterruptedly.

The voltage stabilizer consists of:

Transformer;

Control boards;

Input filter;

Indication display.

This is what the stabilizer looks like

Three types of failures can occur in the power supply network of a gas boiler - complete power outage, pulsed high-frequency interference and short-term surges/drops in voltage. To solve the first problem, there are uninterruptible power supplies. But the stabilizer of the appropriate power is responsible for smoothing the other two.

Stabilizer connection diagram

The filter at the input, assembled from chokes and capacitors, fights impulse noise. The equalization of electric current parameters during voltage dips is carried out by a transformer, which, as necessary, uses various windings in its composition. It is controlled using semiconductor switches, relays or an electromechanical roller (servo drive).

Types of voltage stabilizers for gas boilers

Corrective voltage stabilizers for gas boilers are single-phase and three-phase. Here, when choosing, you need to focus solely on the number of power phases of the water heater.

Based on the winding switch used on the transformer, household stabilizers are divided into three types:

Relay (electronic).

Semiconductor based on thyristors or triacs.

Electromechanical.

Each of them has its own advantages and disadvantages. Some of them can be used with gas boilers, while others are not worth it at all.

Among the advantages of relay voltage stabilizers are:

High response speed;

Resistance to power overloads;

Reliability and durability (service life of 5 years is the norm);

Maintainability;

Low price.

Relay model

To return the output voltage to acceptable limits, these stabilizers require literally a few fractions of a second. Each relay in them is enclosed in its own sealed housing, which reduces the likelihood of moisture and dust getting inside, as well as the occurrence of sparks and short circuits to zero.

The main disadvantage of relay models lies in the pronounced stepwise voltage at the output (each step is 20–25 V). Plus, when switching, the relay clicks slightly and causes a small jump in the output voltage of 5–15 Volts at the moment of operation. If the boiler equipment is equipped with high-precision electronics, then it is better to look for a stabilizer for a different type of gas boiler. This option can disable microprocessor automation.

Semiconductor voltage stabilizers have the following advantages:

The longest service life is 10–15 years;

High precision and steps of only 2–10 V;

Wide range of operating input voltage;

Reliability, compactness and noiselessness.

This is the most optimal voltage stabilizer option in terms of characteristics if it is selected for a gas boiler. Its only drawback is its relatively high cost. But it will last much longer than other analogues. However, such a stabilizer should be taken into the boiler room exclusively in the triac version. Thyristors produce a voltage that is far from sinusoidal and during operation themselves produce interference.

Electromechanical voltage stabilizers are famous for:

High accuracy of 2–3%;

Smooth adjustment;

Lack of steps in the output sinusoid.

Such a device is distinguished by excellent performance in terms of accuracy and smoothness of electric current stabilization.

However, it is not recommended to use an electromechanical voltage stabilizer for a gas boiler. It has a moving graphite brush, which sparks when it comes into contact with the transformer windings. But gas and sparks in the same room are incompatible things.

Due to the presence of moving parts, the electromechanical voltage stabilizer does not last long (only about 1–3 years) and requires regular maintenance. The brush should be cleaned from dust at least once a year. Plus, their switching speed reaches several seconds; a gas boiler needs a faster power supply stabilizing device.

How to choose a voltage stabilizer?

When choosing a stabilizer for a gas boiler, you should look in its passport for:

Input voltage range;

Output power (volt-ampere characteristic);

Number of boiler power phases;

The device itself is protected from short circuits;

Speed of response to changes in input current;

Installation method (there are wall and floor models);

Guarantee period.

The larger the stabilizer has a range of input U from min to max, the better. However, expanding these limits will come at a cost. And often this is simply not necessary. You should focus on the realities of the network from which the boiler will receive the power it needs. Here it is best to pick up a voltmeter and take measurements over the course of several days to determine exactly what is happening with the current in the outlet.

The most important parameter is the power of the stabilizer. This is the load that the device can “pull” during operation. To calculate this figure, you need to sum up the consumed Watts of the boiler and circulation pump (if there is one). This will be what the heating system requires for normal operation. Plus you need to add another 30% in reserve.

However, when turned on, the pump electric motor supplies a starting current to the network, which can exceed the rated current by 3–5 times. This happens within literally a second, but the stabilizing device must be able to withstand the surge of this reactive component without any problems. If it does not provide appropriate protection, then the current-voltage characteristic of the stabilizer will have to be overestimated in order for the device to withstand everything.

At the same time, its power should not exceed the parameters of the machine in the panel, otherwise the network protection will constantly be triggered to turn off the electrical power. Such a load calculation is done individually for a specific set of gas and related equipment. There is no room for error here.

If the electrical network at home “pleases” with constant surges, then it is recommended to purchase a wood-burning boiler in a non-volatile version. He definitely doesn't need a voltage stabilizer. This stove only needs wood or pellets.

Model RUCELF SRW-10000-D, price about 8,000 rubles