How to install a heating boiler with your own hands. Installation of heating boilers - how to install a solid fuel boiler with your own hands

It often happens that in a private house there is no possibility of connecting to central communications, due to the great distance from the latter. This problem is especially relevant for new cottage settlements, which are actively populated, but communications are planned to be installed in the next couple of years. If you find yourself in such a situation and want to live in your own house next winter, the best way out for you is to equip an autonomous heating system with your own boiler room.

In most cases, cottage owners prefer solid fuel models of boilers that run on wood, coal, and pellets. Solid fuels are familiar, effectively cope with their task and are inexpensive.

In this article we will analyze the advantages and disadvantages of different connection schemes for solid fuel boiler equipment, and tell you how to properly install the boiler so that the building's heating system functions smoothly, efficiently and safely.

The procedure for installing a solid fuel boiler in a private house

The installation procedure traditionally includes 3 stages, including:

There are several options for strapping, below we will talk about them in detail.

One of the most important stages, which should be taken as seriously as possible, is the arrangement of the boiler room (furnace) - the room in which the boiler is supposed to be installed. The boiler room must be equipped in accordance with all fire safety requirements, including:

Also, in order to ensure fire safety, it is necessary to leave as much free space around the boiler as possible and not install it close to the wall.

Boiler piping diagrams

Owners of private houses who equip the heating system with their own hands, as a rule, choose the simplest piping scheme. This option involves the connection of boiler equipment to the heating system from two sides - to the supply pipeline and to the return pipeline - through a pair of pipes.

Such a strapping scheme is good in that it is absolutely autonomous in relation to the mains. Even in the event of a power outage, the system will function properly.

The main and very significant drawback is that it is not possible to adjust the temperature of the coolant at the outlet of the heating equipment, which can eventually lead to such adverse consequences as the appearance of rust on the surface of the pipes and the boiler.

This connection option is quite popular due to the fact that even a layman can do it. At the same time, there are more complex piping schemes that imply the possibility of adjusting the temperature of the coolant, which should not fall below 60 ° C, and, at the same time, boiling is also highly undesirable. Compliance with this condition allows you to exclude the following adverse events:

- a regularly occurring large temperature difference in the heat exchanger, contributing to a reduction in the service life of the equipment and its non-repair operation;

- condensate formed on the inner surface of the combustion chamber.

The latter is especially important, since condensate is nothing more than weak solutions of acids of low concentration that can corrode the walls of the boiler.

Basic strapping scheme

When choosing a method of connecting a solid fuel boiler to the heating system, special attention should be paid to the installation of the mixing unit, as well as the safety group. The latter is the first element of the system encountered on the path of the heated coolant. The security group includes:

- pressure gauge that monitors the pressure in the system;

- safety valve - discharge of excess coolant and steam;

- air vent, eliminating the occurrence of air jams;

Such equipment is presented in the "Related Products" section of our online store under the name "Security Group". Its main purpose is to ensure trouble-free operation of the heating system. The pressure gauge, air vent and valve are mounted on a single manifold made of stainless steel. It allows you to reduce the pressure in the system automatically.

We recommend reading our article Types of automatic safety gas boilers on our Zen channel.

Installation of the mixing unit

Upon completion of the installation of the safety group, you can proceed with the installation of the mixing unit - the return jumper that docks the supply circuit of the heating system with the return. During the operation of the system, the liquid, bypassing the heating devices, gives off heat and returns to the boiler for heating.

If this circuit works correctly, when the coolant temperature drops below 60 ° C, the jumper will open automatically, a small amount of hot water will enter the return circuit and the temperature will return to the desired value.

Solid fuel boilers "Kupper" are universal heating equipment capable of operating in open and closed systems, where forced or natural circulation of the coolant is provided. Such a boiler can act both as an independent source of heat energy, and as an additional one - as part of an existing heating circuit, in tandem with another boiler that runs on gas, electricity or liquid fuel.

An additional advantage of buying a Kupper boiler from Teplodar is that a thermometer for temperature control is included with the heating equipment.

Connecting a solid fuel boiler with a heat accumulator

If the boiler does not have the option of automatic fuel supply, you will have to monitor the amount of the latter in the furnace yourself and periodically load a new portion into the flame. The more actively the boiler is heated, the more intensively the heating system works. This is not very convenient, because a lot of time is spent on the above manipulations to maintain the desired temperature in the room.

A buffer tank will partially cope with this inconvenience - a kind of heat accumulator, which is a water tank, the heating of which comes from the supply circuit of the heating system. The list of advantages of its installation are:

- the possibility of reducing the elevated temperature of the coolant at the peak of the boiler;

- heat transfer to the cooled coolant with a decrease in the temperature of the liquid in the system.

Such a heat accumulator cools down for quite a long time. When choosing a buffer tank, proceed from the fact that for a house with an area of 150 m 2 you will need a tank with a volume of at least 1 m 3.

Additional mixing unit

An additional mixing unit is mounted in the area between the buffer tank and the heating radiators. This element of the system connects the return and supply circuits and avoids a strong temperature difference, when the coolant at the peak of the boiler begins to almost boil.

By the way, for Kupper solid fuel boilers with an automatic pellet burner, an additional mixing unit is not needed, and when installing them, you can safely limit yourself to the most primitive piping scheme.

In the Kupper OVK 10 model, an automatic pellet burner (APG) is installed in place of the ash door of the boiler, and the container into which the pellets and the built-in control panel are loaded are installed on the boiler itself, which saves space in the room. Before starting the workflow, the parameters of the heating system are set on the remote control. Using an automatic remote control, you can control the ignition, the combustion process and maintain a balanced temperature of the coolant without the participation of additional mixing units that complicate installation. Another advantage of this model is that the ash is partially removed by the built-in high power fan.

Such a boiler is suitable for installation in rooms up to 100 m² and can be used in a residential building, in a country house, in a garage, and other places. The equipment can be easily included in heating systems of various types. A nice bonus is the presence of a stove with a hob.

Emergency circuit connection diagram

One of the obvious and most frequent problems that occur in heating systems with solid fuel boilers is overheating of the coolant. It is highly undesirable to allow the conversion of hot water into steam and cool it in a timely manner to the desired performance.

There are three simple and effective methods of coolant cooling:

- In the furnace, in addition to the main one, an additional heat exchanger is mounted. The first will work to heat the coolant, the second - to provide cooling of the liquid. The inlet pipe connects to the water supply, and the opposite one - to the sewer. If you need to urgently cool the coolant, simply unscrew the valve on the pipe, and cold water will flow into the second heat exchanger.

- In the process of arranging the system, one heat exchanger is mounted inside another, which ensures a quick decrease in the temperature of the working fluid, if necessary.

- Two pipes are connected to the branch pipes of the heat exchanger, the first is connected to the water supply, and the second to the sewerage. Next, a valve is mounted that provides cold water supply to the system. Excess coolant is discharged into the sewer.

All three methods are equally effective and achieve the same result.

Additional wiring diagrams for a solid fuel heating boiler

We recommend paying attention to such an important circumstance that directly affects the choice of a piping scheme for solid fuel boilers as power outages that occur from time to time. This is fraught with a sharp boiling of the coolant with all the ensuing consequences. This problem can be solved by installing a bypass, which will isolate the circulation pump from the heating circuit.

Bypass (siding) - a backup pipeline through which the coolant can be supplied bypassing some section of the main pipe or in parallel. At one end it is connected to the inlet pipe, the second - to the outlet. The bypass is often used to install additional devices on it, for example, shut-off valves, with which, if necessary, block the water flow in the main line, redirecting it to the spare. To completely shut off the system, the outlet pipe is equipped with a tap. Shut-off valves can also be mounted on the bypass, on the inlet pipe.

Combined boilers

Recently, combined boilers that provide continuous heating of the coolant, regardless of external circumstances, are gaining more and more popularity. The system can be supplemented with another boiler, gas or electric. The scheme for connecting an electric boiler to a solid fuel boiler is carried out in a parallel way. Equipment with a tie-in to the supply and return circuits is added to the piping. Shut-off valves must be installed at the junction of two connections. In the case of an automated system, a 3-way valve with a thermal head is used.

The assortment of our online store includes models of boilers that can be used in such schemes, for example, "Kupper Praktik 20". This equipment is designed for heating rooms with an area of 130-200 m 2 and can work both on coal and on wood. Thanks to its compact size, it takes up little space. Another option, "Kupper Praktik 8", is intended for small rooms from 40 to 80 m 2. Due to the presence of the heating element block, the coolant temperature is maintained for some time after the fuel has burnt out.

A solid fuel boiler has a large number of advantages, including high efficiency, ease of installation and heat generation, with extremely low fuel consumption. Due to this, solid fuel boilers are becoming quite popular, especially when organizing heating in private homes or cottages. How to install and connect a solid fuel boiler, we will consider further.

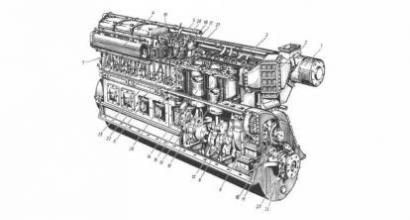

Solid fuel boilers - photos and installation benefits

The installation of solid fuel boilers is primarily associated with those regions in which, for some reason, there is no gas or electricity supply. In addition, solid fuel boilers have the following advantages:

- a wide range of fuels used for home heating, in addition to traditional wood and coal, solid fuel boilers run on peat briquettes, pellets, etc., there is the possibility of choosing the most optimal type of fuel;

- economic aspect - this advantage is important, because the cost of heating with a gas boiler can significantly save on heating costs, especially in the winter season;

- duration of operation - when choosing the right boiler equipment, this type of boiler is able to serve its owners for many years;

- independence is the main advantage of solid fuel boilers, because such a unit will always work, regardless of the presence of electricity or gas;

- a variety of models allows you to choose a boiler with the optimal power that fits the individual parameters of the room.

Among the disadvantages of solid fuel boilers are:

- the need for an additional room in which fuel will be stored;

- the impossibility of installing a multi-storey building in an apartment;

- the need to install a chimney and additional costs for its arrangement;

- to obtain the desired efficiency, it is necessary to create certain conditions in the form of draft and oxygen supply to the furnace;

- if you choose cheaper models, then their operation will take a long time, since they need periodic cleaning of soot, in addition, the boiler must be cleaned of fuel combustion products;

- the need for manual loading of fuel;

- The efficiency of solid fuel boilers directly depends on their type, for long-burning boilers it is lower, about 69%, for standard ones up to 85%;

- the need for additional care and the need to equip the boiler with various kinds of mechanisms, such as a thermal accumulator, thermostat, forced draft, etc.

Therefore, the issue of buying a solid fuel boiler should be decided based on the above advantages and disadvantages of these devices. You should also compare the individual parameters of the room and the type of boiler, since if there is no gas in the area, then the installation of a solid fuel boiler will be the best solution.

In relation to the principle of combustion, solid fuel boilers are:

1. A solid fuel boiler for a house with a classic type of combustion - such boilers have an impressive firebox, natural combustion of fuel is carried out in it. The design has sensors that control the temperature inside the boiler, as well as a mechanical control damper. This type of boiler is distinguished primarily by unpretentiousness and ease of maintenance.

For its performance, various types of fuel are used, in the form of a briquette, firewood, coal. Another advantage of such boilers is their affordable cost, ease of operation and maintenance.

However, this type of boiler has the following disadvantages:

- short period of fuel burning, the need for constant loading;

- low level of efficiency, the need to process more fuel to produce heat;

- the need for frequent daily cleaning of the boiler;

- all heating processes are carried out manually and require constant monitoring.

It is possible to mount a tank to this boiler, which accumulates heat, this element has the form of a steel tank, which has good thermal insulation characteristics. Its main function is the accumulation and preservation of heat during the operation of the boiler.

2. Long-burning solid fuel boiler - this type of boiler does not have the previously described disadvantages. There are two options for solid fuel boilers for long burning:

- pyrolysis type;

- smoldering type.

The first option is distinguished by the presence of two chambers, in the first of which the fuel is burned without the participation of oxygen. Since the fuel is exposed to high temperature, wood gas is released. Further, the fuel enters the second chamber, it contains oxygen in excess. At the same time, the level of efficiency in such boilers is more than 91%. A full load of the boiler ensures its functioning without human intervention, for twelve hours. After the combustion of fuel, there is practically no ash left, so the boiler is cleaned every four or five days.

If you plan to heat a small house with an area of 50 square meters, then this will require about 5.5 kg of fuel per day.

Among the advantages of these boilers, note:

- variety of fuels used for heating;

- automated operation of the boiler;

- duration of burning without human intervention.

The second option is a smoldering cauldron, in which combustion is carried out in the form of a candle, that is, starting from the top, moving to the bottom. These boilers are distinguished by a large combustion chamber, so they are able to work without human intervention, for 4-8 days.

The cost of this type of heating will be cheaper than the previous option - pyrolysis boilers. However, the fuel must meet certain specifications, first of all, have a moisture content of about fifteen percent. In addition, in the presence of resins in the fuel, these boilers begin to work poorly, therefore, the choice of fuel and the conditions for its storage should be approached very carefully. Otherwise, such a boiler will have to be cleaned more often.

There are certain characteristics by which solid fuel boilers are chosen:

- type of fuel - when heating with coal, it is recommended to choose devices based on high-carbon steel, for firewood - a cast-iron boiler is suitable;

- power of boiler equipment - this characteristic indicates the amount of fuel loaded into the boiler at a time, in addition, the area to be heated directly depends on the power of the boiler;

- the type of material from which the boiler is made, for example, comparing the power of a steel and cast-iron boiler, to install the first option at the same power as the second, less space will be required;

- the cost of installing steel boilers is much less than that of cast iron ones, this is primarily due to its weight;

- Efficiency - the cooling of the cast-iron boiler is slower, however, it will also take more time to heat up, while steel boilers have a higher efficiency;

- the amount of costs associated with operation and maintenance - this parameter is also quite important in the process of choosing boiler equipment, so it should be taken into account when buying a boiler;

- the duration of operation of the boiler depends on how it is maintained, the optimal life of solid fuel boilers is about ten years.

Features of installing a solid fuel boiler in the house

During the installation of a solid fuel boiler, special attention should be paid to the correct connection of equipment to the system. In addition, we do not recommend performing installation work without experience with boiler equipment. Since an incorrectly installed boiler can lead to an explosion and harm not only the home, but also the people who live in it.

In the process of installing the boiler, you will have to perform work related to slope calculations, pipe installation, etc. In addition, it will be necessary to install the chimney, calculate the size of the boiler room, and equip it.

Solid fuel boilers have an exclusively floor location, therefore, for their installation, a concrete platform should be prepared in advance. Installation of a solid fuel boiler consists of the following stages of work:

- preparation of the premises for the installation of the boiler;

- installation of boiler equipment;

- strapping;

- installation and connection of the entire system with a chimney;

- start and test the boiler.

The first stage of the work is based on the preparation of the base for the installation of the boiler. It is preferable to make it from concrete, but it is also possible to use steel frames.

The second stage is the most difficult and voluminous in terms of work. Since the boiler must be installed on a previously prepared base, if there are joints between the boiler and the surface, they are sealed with silicone.

two pipes should be connected inlet and return, and if hot water is available, another pipe responsible for delivering hot water to consumers.

The final stage of the work is the installation of the chimney and its connection to the boiler. All work is carried out in accordance with technical requirements and compliance with fire safety rules.

How to install a solid fuel boiler with your own hands

The arrangement of the boiler room is the first and main preparatory stage for the installation of the boiler. There are a number of requirements that apply to the boiler room in which a solid fuel boiler will be installed, we will consider them below:

- the interval between the boiler and any of the walls of the boiler room must be at least 50 cm;

- the distance between the firebox and the wall in the room is 100 cm;

- it is forbidden to store items in the boiler room that are characterized by ease of ignition;

- the location of the ventilation ducts in relation to the ceiling is forty centimeters, and to the floor - fifty;

- walls and floors must be made of concrete, however, it is allowed to cover walls made of other materials with steel, for example.

For additional protection of the site on which the boiler will be installed, it is covered with metal or asbestos. In addition, the place where the fuel tank is loaded must be additionally protected from sparks.

Installation of the chimney should be given special attention, since an improperly installed chimney can lead to poisoning of people staying in the house with carbon monoxide. All connections between the boiler and the chimney must be tight. The diameter and length of the chimney are selected individually according to the power of the boiler and the size of the room. The main requirements for the chimney are:

- ensuring good chimney draft;

- high-quality removal of all gases that are released during the combustion process.

In addition, the installation of equipment involves compliance with the scheme of the solid fuel boiler and the entire heating system. Before carrying out work, a project should be drawn up, which will indicate the length, slope angle, length of each of the pipes in the system.

Please note that the inlet return in the boiler must be organized in such a way that its location is lower than the heating radiator itself. Thus, it will be possible to ensure the normal circulation of the coolant in the system.

In addition, we recommend installing a circulation pump, with which you can adjust the transport of the coolant. If necessary, forced and natural circulation will be organized. If the boiler gets too hot, then by turning on the pump and quickly circulating the liquid, it will be possible to slightly lower the temperature of its heating and prevent the liquid from boiling.

Another important element of the solid fuel boiler system is the installation of special valves that are responsible for the safety of the equipment. With their help, the following actions are carried out:

- removal of too much pressure;

- temperature support up to one hundred degrees in the furnace;

- ensuring the optimal temperature of the thermal carrier.

After performing the previously described work, the most important stage follows, which determines the quality of the installation of a solid fuel boiler - its performance test.

First, visually inspect the entire system, then start cold water. Make sure there are no leaks. For 20 minutes, monitor the system by applying additional pressure to it, so that it will be possible to check the connection of all its parts and their tightness. Next, fuel is installed in the boiler and its operation is checked in the process of its combustion. This stage involves the control of the following aspects:

- equipment performance;

- circulation work associated with the heat carrier;

- fuse performance;

- temperature with the system;

- uniform heat distribution in all rooms.

Solid fuel boilers video:

The key advantage of solid fuel heat generators is energy independence. Such a boiler operates autonomously, without the need for electricity, unlike gas units and electric boilers. In addition, solid fuels are affordable. For self-installation of a solid fuel boiler, you need to understand the installation standards developed for equipment of this type, as well as choose the optimal connection scheme.

Installing a solid fuel boiler in a private house

Compliance with the installation rules ensures the safe operation of solid fuel boilers. A competent approach to the development of a connection diagram will allow the boiler unit to operate with maximum efficiency and save energy.

General installation principles

Installation of a solid fuel boiler in a private house requires careful preparation. At the preliminary stage, the heating system is calculated taking into account the needs for heat and hot water supply. Then a heating boiler of suitable power is selected. If the system provides for the installation of a buffer tank for the accumulation of excess heat, the power of the heat generator should be twice the calculated values.

A special room is being prepared for the installation of a solid fuel boiler. The boiler room must comply with fire and sanitary safety requirements, have effective ventilation, a chimney to remove combustion products, electricity and water supply.

It is required to put a solid fuel unit on a specially equipped solid and even base. The design of the smoke extraction system must comply with the engineering parameters of the boiler. In order to properly install the strapping, it is important to adhere to the scheme agreed with the experts.

The main stages of installation

Do-it-yourself installation of a solid fuel boiler is carried out in the following order:

- The unit is delivered to the boiler room and is released from the factory packaging.

- If, due to lack of space in the boiler room, it is difficult to assemble the heat generator, these works are carried out outdoors. Necessary:

- install an ash box;

- attach all doors.

- The assembled boiler is installed on a prepared base, while the flue pipe must be located strictly along the axis of the chimney mounted in the boiler room.

- The boiler is fixed on a flat base, it is important to prevent distortions.

- A chimney is connected, a control unit and a fan are installed, a safety group is mounted on the outlet pipe of the water jacket.

- Installation of the piping of the boiler unit and connection to the heating circuits is in progress.

Connecting a chimney to a solid fuel boiler

Connecting a chimney to a solid fuel boiler Note! The weight of a solid fuel boiler usually exceeds 50 kg, when planning to install the boiler on your own, invite an assistant.

Boiler room: key requirements

Before installing a solid fuel heat generator, it is required to prepare a boiler room. It should be a separate room in the house itself or an extension. If the boiler room is located in the house, it should provide a separate entrance from the yard for the convenience of fuel delivery.

List of basic requirements for the boiler room:

- area not less than 7 m 2;

- the presence of effective supply ventilation (the cross section of the ventilation duct depends on the power of the heat generator - from 8 cm per 1 kW);

- the site for the installation of the boiler must be located at a distance from the walls so that a gap of at least 50 cm is maintained between the unit and the walls;

- the floor covering must be made of non-combustible material (concrete, tile), sheet non-combustible material is laid in front of the firebox, usually a steel sheet;

- the diameter of the chimney must correspond to the parameters of the flue outlet of the boiler unit;

- water supply and electrical wiring is carried out taking into account all fire safety requirements.

Important! Before arranging the boiler room, it is necessary to familiarize yourself with the documentation for the selected heat generator so that the room fully complies with the specific parameters specified by the manufacturer.

Installing a solid fuel boiler in a wooden house requires special attention due to the increased fire hazard. In the boiler room, a concrete floor is poured or a separate foundation is prepared for the heat generator, the walls are sheathed with non-combustible material.

Formation of the foundation for a solid fuel boiler in a wooden house

Formation of the foundation for a solid fuel boiler in a wooden house Boiler units of low power are installed directly on a flat concrete floor screed. For solid fuel boilers with a power exceeding 50 kW, it is necessary to equip a separate foundation on the ground with a sand and gravel pad. The foundation base for the boiler should rise 8-10 cm above the floor level and not come into contact with the foundation of the building, as well as the floor screed in the room.

It is important to install a solid fuel boiler in such a way that its efficiency corresponds to the passport indicators. To do this, you need to choose and install the chimney correctly, on which the maximum possible draft intensity depends.

The following requirements apply to the chimney:

- lack of turns (if they cannot be avoided, turns cannot be made sharp);

- high-quality sealing of all joints of the pipe, the junction of the chimney to the branch pipe of the unit (a special sealant or heat-resistant tape is used);

- structural strength is laid with a margin for unplanned external loads;

- the cross section of the chimney pipe must correspond to the format of the flue pipe of the boiler.

Natural exhaust ventilation (the overflow grate is installed under the ceiling of the boiler room or the shaft is mounted parallel to the chimney) performs the following functions:

- creates a vacuum, due to which the air supply necessary for the combustion process is ensured (when installing boilers with a capacity of 50 kW or more, supply ventilation is required);

- removes combustion products that have accidentally entered the air of the room.

It is recommended to lead a sewer pipe into the boiler room in order to have a convenient drain for dumping the steam-water mixture by the safety valve, as well as for draining the coolant from the boiler jacket and the heating system before carrying out maintenance or repair work.

Boiler in a heating system with natural circulation

The easiest way is to connect a solid fuel boiler to a gravity heating system. The supply and return pipelines are connected to the corresponding branch pipes of the heat generator. A safety group is installed on the outlet pipe - a manifold on which a pressure gauge, an emergency pressure relief valve and an air vent are mounted. An expansion tank is installed at the highest point of the heating system.

General installation scheme of a solid fuel boiler with a natural circulation system

General installation scheme of a solid fuel boiler with a natural circulation system This installation scheme for a solid fuel boiler is used for heating systems with natural movement of the coolant and a pipeline installed at a slope to improve circulation. Such installation of the boiler makes it possible to organize an autonomous heating system, independent of the power supply, in which solid fuel units without automation are involved.

Heating with forced circulation

The installation scheme for a solid fuel boiler for a heating system with forced coolant supply provides for the installation of a bypass and a three-way valve to create a primary circulation circuit.

Installation of a solid fuel boiler in a forced circulation heating system

Installation of a solid fuel boiler in a forced circulation heating system This principle of connecting solid fuel boilers eliminates the formation of condensate in the combustion chamber of a steel boiler or the destruction of a cast-iron unit when a cooled coolant enters the water jacket of a red-hot heat generator. A three-way valve set to a predetermined temperature and a bypass allow the heated coolant to be mixed into the return until the heating system reaches the optimum operating mode.

The scheme for installing a solid fuel boiler may include a tank for preparing water for hot water supply - an indirect heating boiler. Its heating element is a coil, through which the coolant heated by the boiler passes.

Schematic representation of the installation of a solid fuel boiler with an indirect heating boiler

Schematic representation of the installation of a solid fuel boiler with an indirect heating boiler In the above diagram, the boiler and heating branches are installed in parallel, directly after the primary circulation circuit. This connection allows you to prepare water for hot water supply, using the most heated coolant. A through thermostatic valve, which is mounted at the outlet of the boiler, does not allow the coolant to freely pass through the coil. It passes water that has cooled to the set temperature, which gave off heat for hot water supply.

The complexity of tying the boiler unit is also affected by the presence of a second heat generator (gas or electric boiler), the number and types of heating circuits (radiator heating, underfloor heating).

There are different schemes for connecting two different fuel boilers to service one heating system. The best option is to use a heat accumulator (buffer tank), to which a solid fuel unit and an electric boiler are connected, each with its own circulation pump. The electric heat generator is switched on by a signal from the controller with an air temperature sensor, when the room temperature begins to fall after the fuel burns out in the main unit and the coolant in the system cools down.

The nuances of installing solid fuel boilers

Installing a solid fuel boiler can be done by hand, but at the same time factors affecting the efficiency of the heat generator should be taken into account:

- type and quality of fuel, completeness of its combustion;

- wind rose and wind strength;

- design features of the chimney;

- the level of protection of the building from heat loss.

Protecting your home from heat loss

Protecting your home from heat loss Good thrust is a necessary condition for the most complete combustion of solid fuel, which ensures high heat transfer. The combustion of wood in conditions of oxygen deficiency leads to an increased formation of carbon monoxide and soot, and a decrease in the heat transfer of the fuel. So that the coolant does not overheat to boiling during the operation of solid fuel boilers in the optimal mode, a buffer tank is installed in such heating systems, the water in which absorbs excess heat. The heat accumulator gives the accumulated thermal energy to the water circulating in the heating circuit for several hours after the fuel load burns out. This makes it possible to reduce the amount of harmful emissions and save wood fuel.

When organizing a heating system with your own hands, special attention should be paid to the chimney:

- provide thermal insulation of the pipe passing outside the boiler room;

- organize a condensate collection system;

- provide inspection hatches for cleaning the chimney;

- provide easy access to the pipe on the roof for maintenance.

When designing a heating system, it is important to correctly calculate the diameter of the pipeline - the circulation intensity and the volume of the coolant depend on this parameter, which is especially important for gravity systems.

By choosing for a home heating system, you can save a lot of money. Moreover, to reduce costs not only during the operation of the equipment, but also during its installation, having done all the installation work with your own hands. Where to place the heating equipment, how to properly install, connect and start the boiler - you can solve these issues yourself, following all the recommendations and requirements for the work being done.

Installation Requirements

The room with the heating installation must have a window for ventilation, a smoke exhaust system, ventilation, walls and partitions from non-combustible materials. It also requires a special base where the device will be placed.

A screed is enough for a low-power boiler; for more powerful equipment, you need to pour concrete foundation, protruding beyond the unit on each side by 20-25 cm. The need for a strong support is caused by the large weight of high-power devices, as well as the load from vibration. A solid base is also required for long-burning boilers with a load lifting and lowering mechanism. To avoid fire, do not place the appliance on a wooden floor.

Proper combustion of solid fuel is ensured by the natural quality ventilation. To calculate the size of the grate with holes, the power of the boiler and the dimensions of the room are required. Existence of an extract allows to remove products of burning, to compensate the rarefaction created during heating by fresh air.

Heating equipment that burns fuel must have a smoke exhaust system. If it is not provided in the boiler room, you need to install it yourself. Chimney requirements:

- no bends;

- the same section of the pipe throughout;

- the length must create the necessary air depression of at least 10 Pa;

- the presence of a spark arrestor.

A metal double-walled chimney with insulation is most often installed to a solid fuel appliance.

The duration of the cold season in our country poses a number of pressing issues for the inhabitants of private houses related to the organization of normal and efficient individual heating. For residents of the private sector in cities and towns of the country, the issue of organizing autonomous heating has been largely resolved through centralized gas supply. A completely different situation has developed with objects of individual residential development. Quite often, due to the lack of central gas supply, for homeowners in the private sector and in country houses, the only way out of this situation is to install autonomous heating boilers on solid fuel.

Heating solid fuel boilers, which are produced today by domestic and foreign manufacturers, are complex high-tech devices. Proper installation, compliance with the necessary rules during the subsequent operation of complex heating equipment will allow you to create the necessary comfort in your home and provide your home with the desired warmth during the long winter.

The most crucial moment is connected with the installation of equipment and its connection to the home heating system. Solid fuel boilers of different types have their own design features, so during installation it is necessary to strictly follow certain rules and comply with the project. If you can figure out the choice of a boiler model on your own, then the question of how to install a solid fuel boiler cannot be answered simply and unambiguously. Work on the installation of any heating device requires competent actions and a qualified approach. Let's deal with this task in detail.

Preparation. What precedes the installation of a solid fuel boiler

Assessment of the scope of the upcoming boiler installation work

The initial preparatory steps that precede the direct installation of boiler equipment are no less important than installation work. Any boiler, gas, electric or solid fuel, is a mini-boiler room, so the installation of the unit is preceded by the design work of the entire heating system.

Buying a solid fuel boiler is just the tip of the iceberg. In the future, it will be necessary to perform a large amount of work for the equipment of the entire heating system. The complex of works on autonomous heating equipment includes the following stages:

- laying pipes inside residential premises;

- boiler room equipment;

- binding of the heating unit;

- starting the heating system.

Assessing the scope of work at each stage, we can conclude that the installation of a solid fuel boiler in a residential building is a complex, time-consuming and responsible process.

Important! Installation of an autonomous heating system, in particular, installing a boiler, is a task that only a trained person can do. Superficial knowledge about the design of heating equipment, neglect of existing standards, norms and rules can cause irreparable harm not only to a residential facility, but also endanger the lives of the inhabitants of the house.

Approximately such a set of fixtures and equipment you will need for.

At the preparatory stage, it is necessary to decide whether we do the heating in the house with our own hands or turn to the services of professionals.

We make a decision - we put the boiler ourselves or turn to specialists for help

A solid fuel boiler is usually purchased based on the existing conditions, where and how the boiler will be installed, in what mode the heating unit will operate, what tasks are set for the autonomous heating system. Having a ready-made project at hand, you can evaluate what you will encounter during the installation of boiler equipment. Therefore, a reasonable question arises - you can install a solid fuel boiler in your house with your own hands, or it is better to turn to professionals.

Only self-confidence and the ability to save your own money can encourage you to make the decision to independently install the heating system in the house.

For reference: the equipment of a solid fuel boiler room, including firewood, coal and pellets, can be carried out without official permission. Only during start-up tests, the presence of representatives of the supervisory authorities is necessary to register the commissioning of heating equipment.

When installing a boiler in your home, you must remember that in the process of work you will need to strictly adhere to the design data. This applies, first of all, to the ventilation and chimney systems. Properly made hood and chimney - a guarantee in accordance with the specified modes. Pellet burners are installed in a solid fuel boiler to increase heating efficiency, but are very sensitive to ventilation.

Before installing the heating equipment, it is necessary to calculate the parameters and equip the boiler room.

Installation of a solid fuel boiler. step by step

Boiler room equipment

To begin with, assuming to install a solid fuel boiler in your home, you should know that this equipment is available only in a floor version. Installation will require you to spend and effort on equipping the boiler room and, accordingly, prepare a special site for the unit.

For this purpose, you need to know your house well in order to choose the optimal room for installing the boiler. The project documentation should contain a diagram of the location of the boiler room in the house. The base for the heating boiler or podium must be of appropriate size and strength. Usually such platforms are made of concrete. The height of such a podium must be at least 7 cm.

The room itself must have an area of at least 7 square meters. m. The boiler should be located at a distance of 0.5 m from the nearest wall of the room. The height of the boiler room should be standard, approximately 2.2-2.5 meters, while the distance from the upper edge of the boiler to the ceiling should be at least 120 cm.

On a note: the only condition, if you installed a boiler with a natural ventilation system, then you will have to think about the height of the ceiling in the boiler room. The flow of air in this case is carried out due to the air masses inside the room. The higher the ceiling, the greater the internal air volume. Remember also the fact that it is more difficult to load the boiler with fuel in a low room.

The installed boiler needs fuel, so next to the boiler it is necessary to equip a place for fuel storage.

Important! Only dry fuel is loaded into the furnace for storage.

A coal pit is specially made for coal. Pellets, briquettes and firewood are stored either in containers or neatly stacked pyramids. The walls in the boiler room must be treated with an 8 mm layer of asbestos. or a thick layer of plaster, thereby protecting house structures. This is especially true when installing a heating boiler in a wooden house.

Retreat: in a number of cases, today traditional boilers are being converted to use pellets. This type of fuel is very convenient and efficient. Pellets are automatically fed into the combustion chamber. In the process of burning this type of fuel, a high thermal effect is achieved, which is very important if a long-burning solid fuel boiler is installed. Installation of a pellet burner is carried out on any solid fuel boiler. This method of operation of the boiler significantly increases the efficiency of heating equipment, especially since the burner can be easily removed if there is a desire to transfer the boiler to the usual fuel, wood or coal.

After preparing the boiler room and foundation, the most difficult and crucial moment lies ahead, the installation of a heating boiler. All the complexity and difficulty at this stage lies in the fact that usually solid fuel boilers are heavy and massive units. Here you need to apply maximum skill and skill.

Working on ventilation and chimney

Any autonomous heating system needs a constant supply of fresh air, which ensures proper combustion of the fuel. Solid fuel boilers, the design of which is based on the furnace principle of operation, must be equipped with a chimney and a ventilation system.

Installing a solid fuel boiler in the house will require you to make additional efforts to create exhaust and supply openings. The first, supply hole with a section of 10x10 cm is equipped at the bottom of the room, opposite the chimney. The second hole is made at the top of the boiler room, the higher the better.

The chimney must be equipped in accordance with the parameters specified in the data sheet of the heating boiler, i.e. it is necessary to accurately select the diameter and length of the chimney pipe. A properly made chimney provides good draft, due to which carbon monoxide, soot and soot are removed.

Important! Excessive draft can adversely affect the regulation of the combustion process of the flame in the furnace and vice versa, weak draft will cause combustion products to enter the living quarters.

The ventilation and chimney installation diagram is shown in the figure. Every setting and size matters. To date, there are a variety of designs of ventilation systems for private houses, starting with brick, massive structures, ending with coaxial chimneys. connection of the boiler to the pipeline system is carried out in accordance with the technical documentation. First, the main circuit is connected, then the return is connected. If provided in the house for hot water supply, it connects the hot water pipeline.

Important! A closed circuit must be equipped with a safety valve, which is installed with the outlet manifold. The task of the safety valve is to operate at an operating pressure of not more than 0.15 MPa.

Installation in a private house involves the use of steel pipes for the pipeline. It is necessary to lay pipes with the least number of turns and bends. The pressure pump is usually cut into a parallel line, in case of a power outage for natural circulation. As a means of protecting the system from overheating, there is a second or spare circuit, through which heat escapes in the event of an emergency to the storage tank for hot water.

Conclusion

The connection diagram of the boiler to the heating system is carefully checked before starting. The main emphasis is on the operation of ventilation devices and pipeline connections to the heating device. If you decide to install a solid fuel boiler with your own hands, perform all subsequent procedures and manipulations, follow the advice of experts and professionals. How to properly install an autonomous heating system in your home, how to equip an exhaust hood and build ventilation, you will have to independently look for a competent answer to these and many other questions.